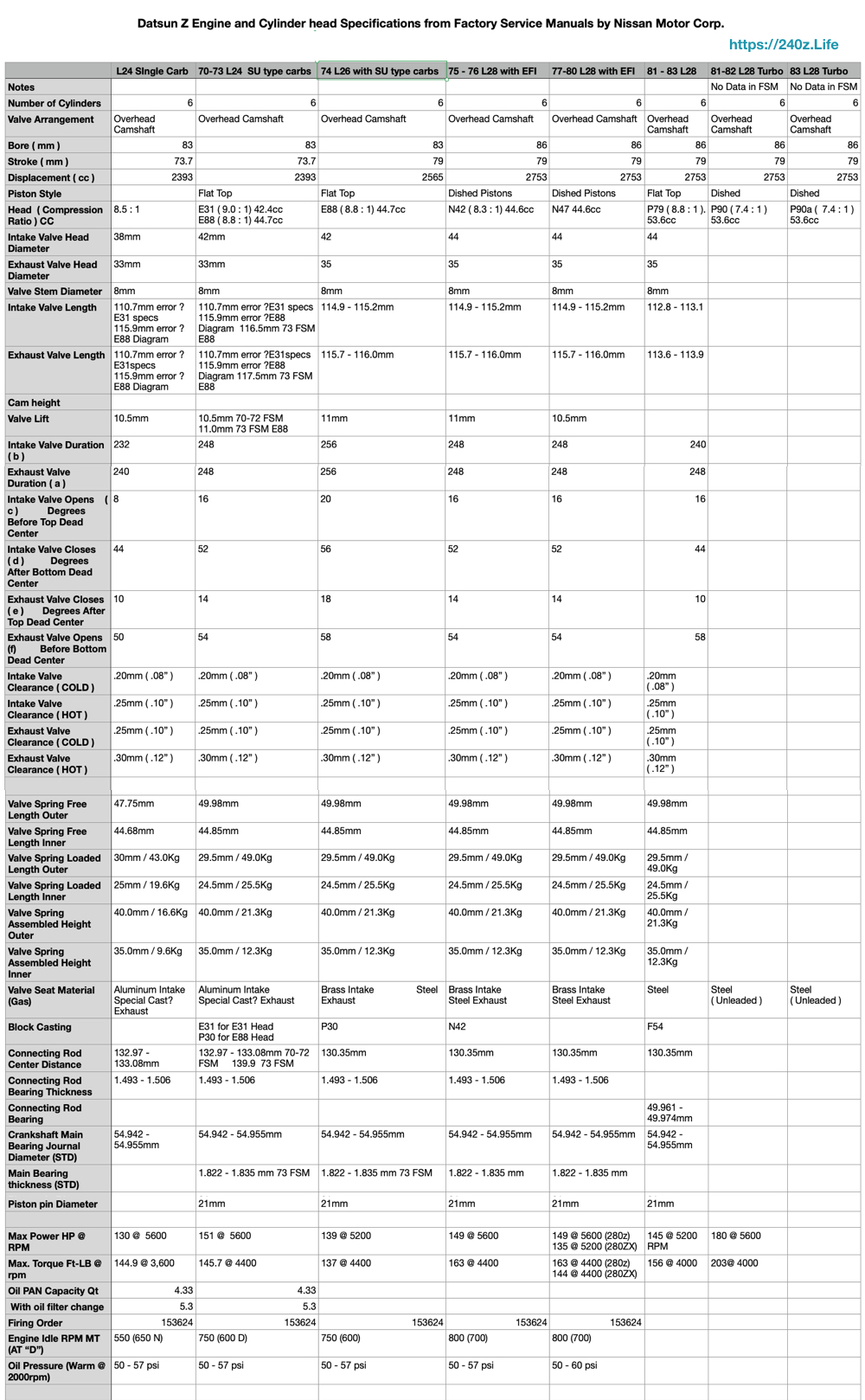

As the Z car evolved, the cylinder heads were redesigned and the Bore and Stoke combinations increased to increase displacement. Below is a table summarizing all of the specifications from the Factory Service Manual by Nissan Motor Corp. It is interesting to see the improvements made for performance and emission controls.

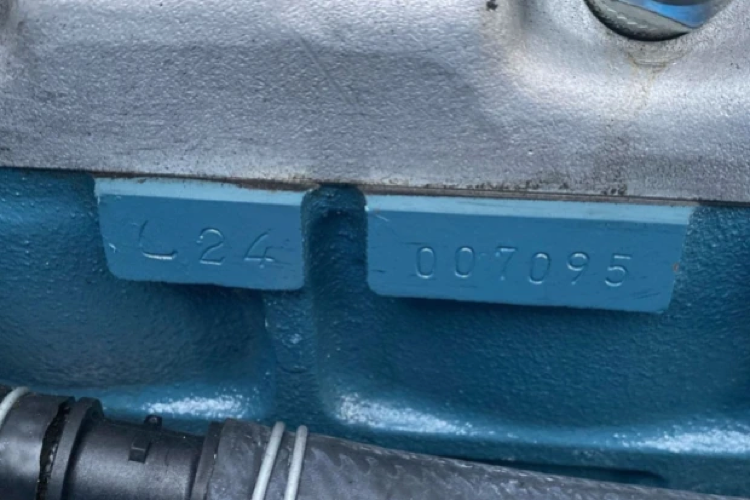

Datsun 240z L24 Block with Serial Number

Image from Internet

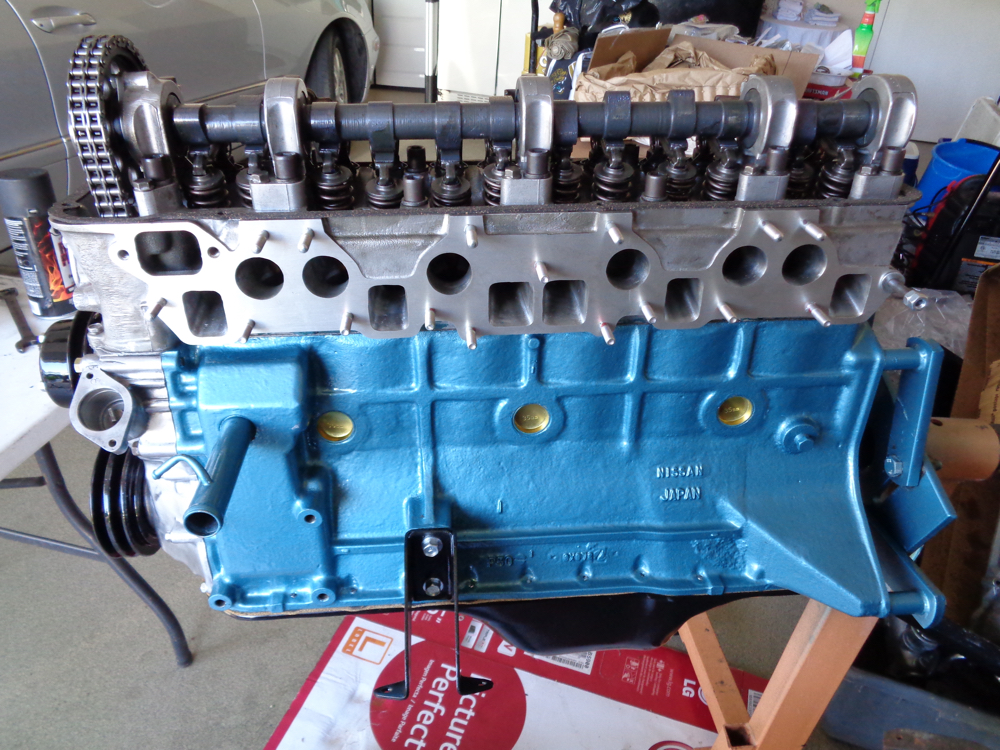

Datsun 240z L24 Block with High Performance E31 Head installed in my 240z “Foxy Lady”

When I started to rebuild the motor for my ground up restoration, I decided to leave the block alone. The numbers matched the id plate, so I wanted to preserve the block. I purchased and had my machine shop install the standard rebuild kit. I prefer to let my machine shop build the block and replace all the components in the head, valve seats and guides. Then I assemble my head, install camshaft components and setup my rocker arm geometry. During the engine build, my main bolts were stretching on assembly.

How to tell if your bolts are fatigued: After torquing everything to spec, come back after a few days and recheck torque settings. If you must re-torque bolts, they are stretching and need replacement. If you can afford it, always replace main bolts, rod bolts and head bolts.

E31 Cylinder Head Installed on L24 with Big Valve Upgrade

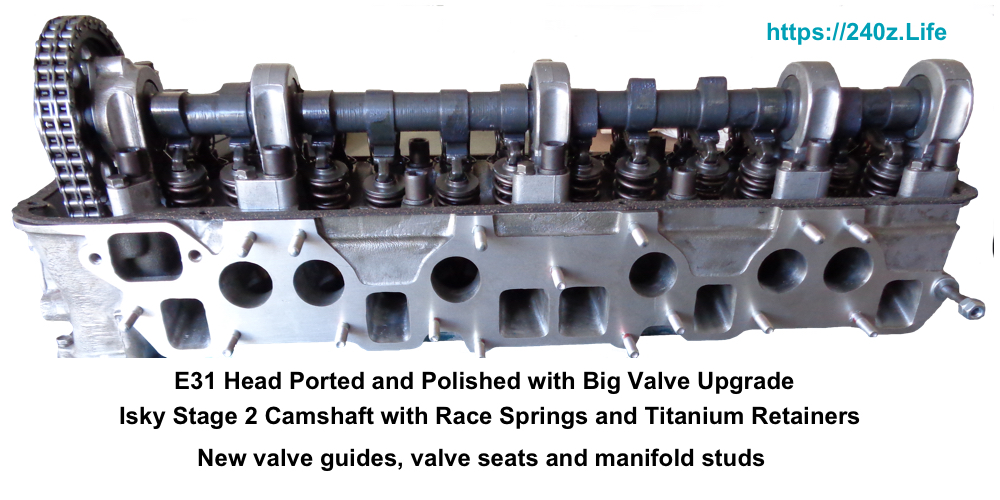

When I built my E31 head, I did it right. I had my machine shop replace the valve seats and valve guides. I installed the hardened cintered iron valve seats, for use with unleaded gas. The intake valve guides were iron and the exhaust guides were a bronze type for better heat transfer.

I upgraded to the bigger diameter valves and used Supertech Intake race valves that were tupiled and shaved, promising 20% more flow. I ported and polished the head to the standard intake gasket. Matching and porting the stock intake and performance exhaust header. Upon assembly, I used a telescopic camera to ensure the port alignment, this is a must otherwise its a waste.

I installed Isky High Performance Valve Train Components: Titanium Retainers, Race Springs, and a Stage 2 camshaft. Running the 280ZX Electronic Distributor with Ignition Control Unit on the side, Performance Headers 6 to 2 to 1 (4″ performance MSA exhaust from Motorsports) and standard SU type Hitachi HJG46W with “SM” needles installed. I was very pleased with the build, she sounds very lumpy at idle and as the rpms increase the power band starts around 2500rpm and she starts to absolutely scream at around 4000rpms.

E31 Big Valve Conversion

Installing 1976 N42 Valves

Intake Valve from 38mm to 44mm

Exhaust Valve from 33mm to 35mm

Intake Valves from Supertech

Exhaust Valves Genuine Nissan

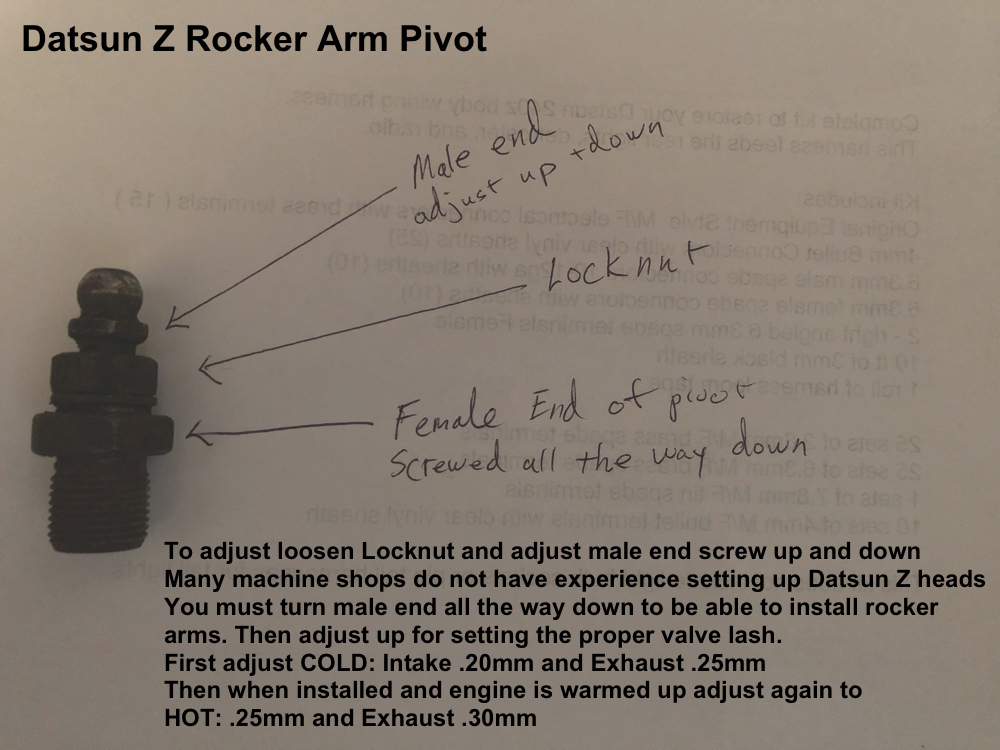

Adjusting the Rocker Arm Pivot for Proper Rocker Arm Geometry

Cross Section of Cylinder Head Nice reference, image from internet.

Mild porting and polishing involves:

Removing casting marks

Porting to manifold gasket and unshrouding material around valve guide and valve seat.

Polishing the Intake and Exhaust chambers

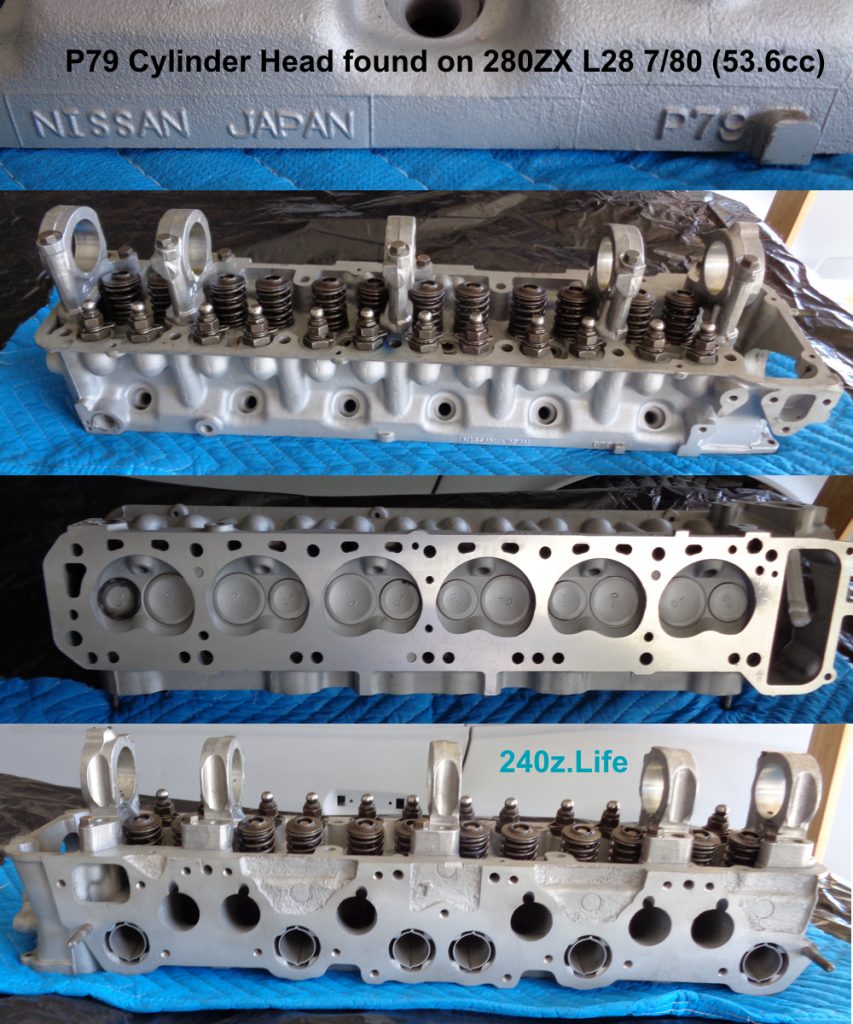

P79 Cylinder head found on Datsun 280ZX (Non-Turbo) with 53.6cc combustion chamber

Datsunzgarage.us has a very nice P79 page check it out!

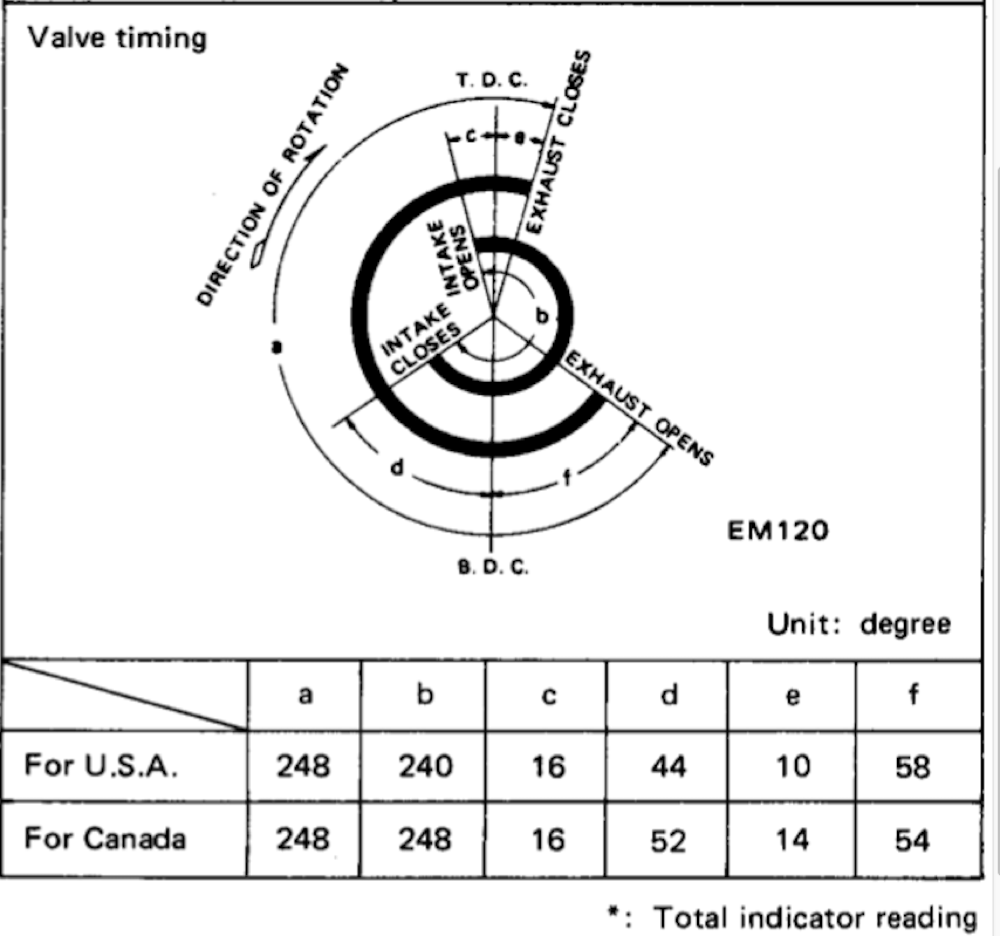

Datsun 280zx Camshaft Valve Timing Chart

The camshaft opens and closes the Intake and Exhaust valves. It is linked to the crankshaft by the timing chain, for perfect timing. A high performance camshaft helps the motor breath better by increase the distance the valve opens ( Stock lift is .420″ My Isky Stage 2 cam has .480″ Lift) and changing the duration the valves are open and subsequently valve overlap by 10 degrees.

The timing chart above shows the valve timing as the piston moves up and down. This motor is a 4-stoke motor. The piston goes up and down twice, 4 strokes to allow fuel and exhaust to move through the engine. A 2-stoke motor has porting in the cylinder head that allow the gases to enter and exit based on piston position. With no valve train components, a 2 stroke motor accelerates much faster.

The breathing cycle of a four stroke motor:

Piston at Top Dead Center (TDC) with Intake Valve Open, piston down stroke, sucks in fuel from Intake Valve (Intake Stroke). Intake Valve closes and piston travels up (Compression Stroke), fuel is compressed and spark plug fires before piston reaches TDC again. The timing of the spark is crucial and is set specifically by adjusting / turning the distributor to adjust the timing of spark plug #1 firing. You use a timing light and timing indicator on crankshaft pulley, to set the recommended spec from the Factory Service Manual, fire so many degrees Before Top Dead Center. As the rpms of motor increase the timing advances to fire the spark earlier, this is crucial for the motor to have maximum power and run properly as the rpms increase. The distributor uses a vacuum advance at lower rpms and a weighted plate that swings out from centripetal forces to advance the ignition timing at higher rpms.

Ignition of the air / fuel mixture occurs, the piston is forced down by combustion gases, know as Power stroke. Piston starts to travel up again exhaust valve opens, this expels the exhaust gas, known as exhaust stroke.

From the stock camshaft timing diagram above we know:

The Intake valve opens 16 degrees before the piston reaches (TDC) Piston going down Intake Stroke.

The Intake Valve Closes 44 degrees after Bottom Dead Center (BDC) Piston going up Compression Stroke.

After Ignition, the piston forced down by expanding combustion gases, the Power Stroke, and the Exhaust valve opens 58 degrees before BDC.

Piston goes up, Exhaust Stroke, and the Exhaust valve closes 10 degrees after TDC and the Intake valve opens 16 degrees before TDC starting cycle again.

Note: When the Intake and Exhaust valves are open at the same time its called valve overlap.

High performance camshafts have increased lift opening the valves more. They also change the duration of the valves opening and increasing the degrees that the valves overlap. A Stage 2 cam increases the duration by about 10 degrees, each camshaft “Stage” usually goes up 10 degrees in duration. This causes the lumpy sound at idle. After about 20 degrees, the motor will not breath properly at idle. The limit of street applications, you will stall at idle or will need to maintain higher rpms so the motor does not stall, this is impractical. Race track applications have increased duration, you maintain engine at higher rpms and do not idle.

Additional Resources

Datsun Z Cylinder head timeline by DatsunZgarage.US formally DatsunZgarge.com

L28 Bore and Stroke Combinations by Jim Wolf Technology Inc. Jim Wolf courtesy of Donn Vickery Unfortunately the links in article are dead links, contact me Jim or Donn and I will link to your website

The Infamous Stroker 3.1L build with 240z 9mm Rods and LD28 Crankshaft Unfortunately website is no longer up and running, however some links are indexed by Geocities

Please contact me author, I will mirror your content. Thanks Great Pics!

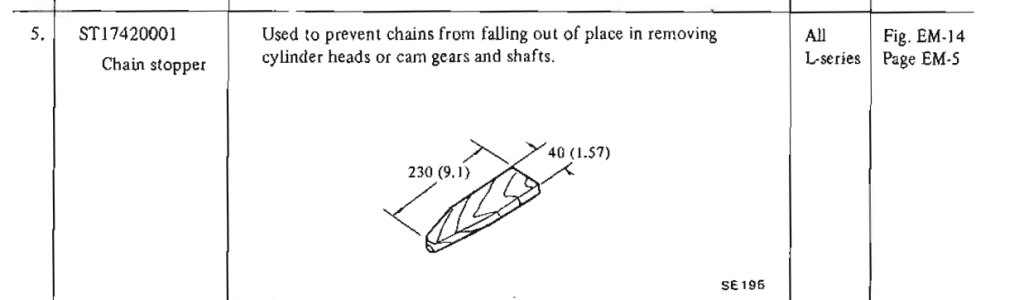

My favorite tool to keep timing chain in place when servicing head. Notice dimensions and make your own, its a wedge and is much better than the hanger type!