There are alot of Datsun / Nissan Transmissions out there. I will focus on the transmissions in the US. Different transmissions were available in different countries. There were also competition transmissions available, with varying gear ratios. The models evolved becoming bigger and stronger than the previous models. The “A” transmissions were the first, and are known as the weak transmissions.

Datsun Manual Transmissions F4W71A and FS5W71A and Automatic 3N71A

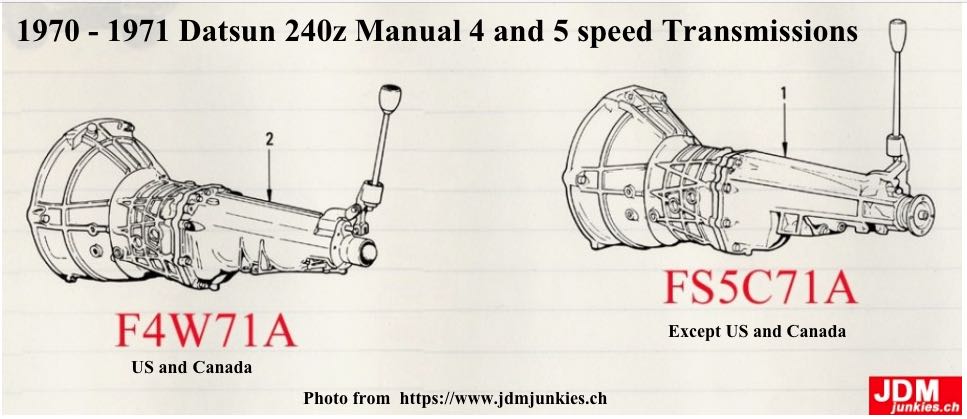

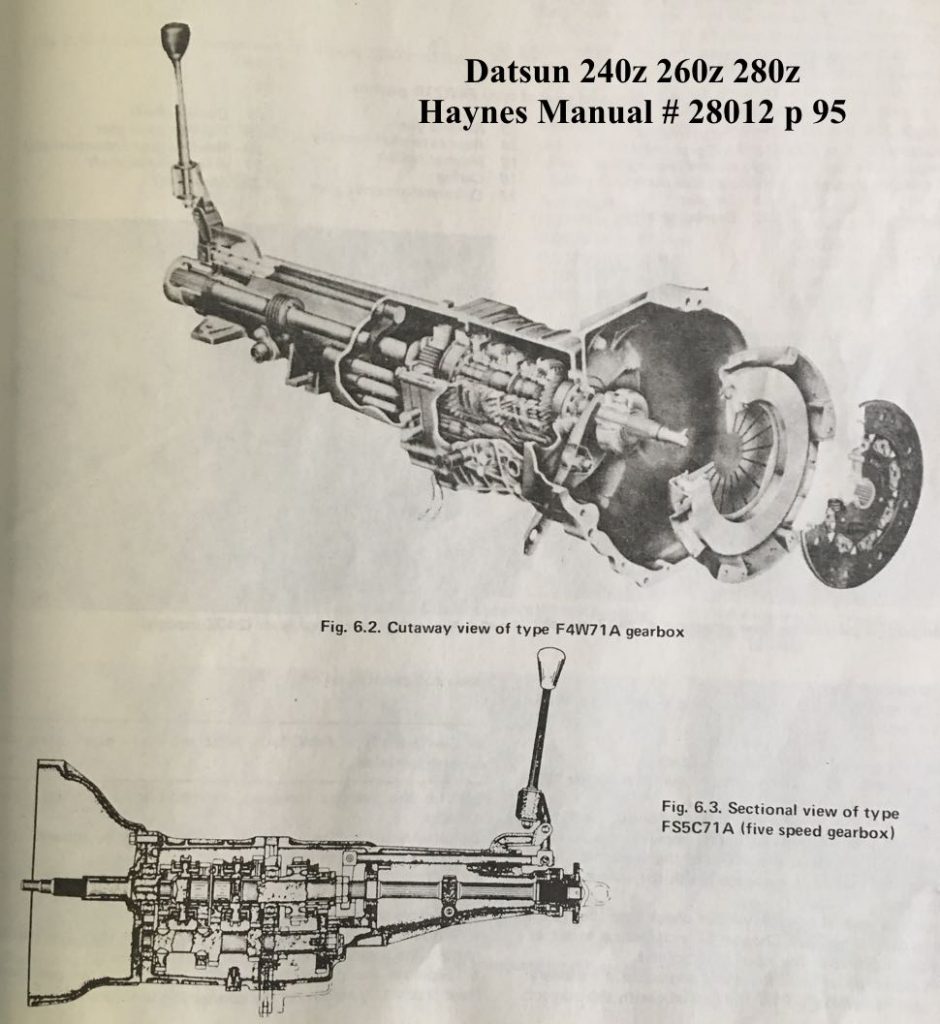

The 1970-1971 Datsun 240z USA model came with a 4-speed manual transmission designated as F4W71A. The FS5C71A was a 5 speed manual transmission version, not available in the US! These transmissions are the easiest to identity. It has 3 piece case and the shifter is raised above the transmission.

The Automatic transmission 3N71A did not come in the US Datsun 240z, but I wanted to provide some information. Im not sure what Nissan did to redesign the “B” model, 3N71A.

Datsun Manual Transmission F4W71B and FS5W71B

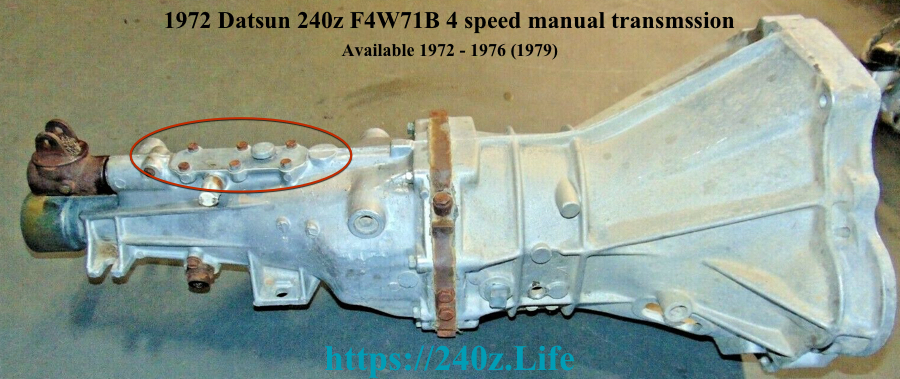

The “B” transmissions came in the 1972 240z, 260z, 280z and 280ZX. The 4 speed MT is designated as F4W71B and the 5 speed version is FS5W71B. There is some mixed info on when the 4 speed was available, Z friends say 1972 to 1976, but Chilton Manual # 2800 says 1972 to 1979.

It is easy to identify the 4 speed MT is designated as F4W71B, the rear extension housing has a removable cover to access the striking rod and lever. When you shift gears this rod and lever move to actuate the internal shift forks. The Automatic Transmission designated as 3N71B made by Jetco was Nissan’s only automatic transmission used in Z cars. The gear ratio and housing appear to be the same as the 3N71B.

The Datsun 4 speed manual transmission F4W71B from 1972 Datsun 240z

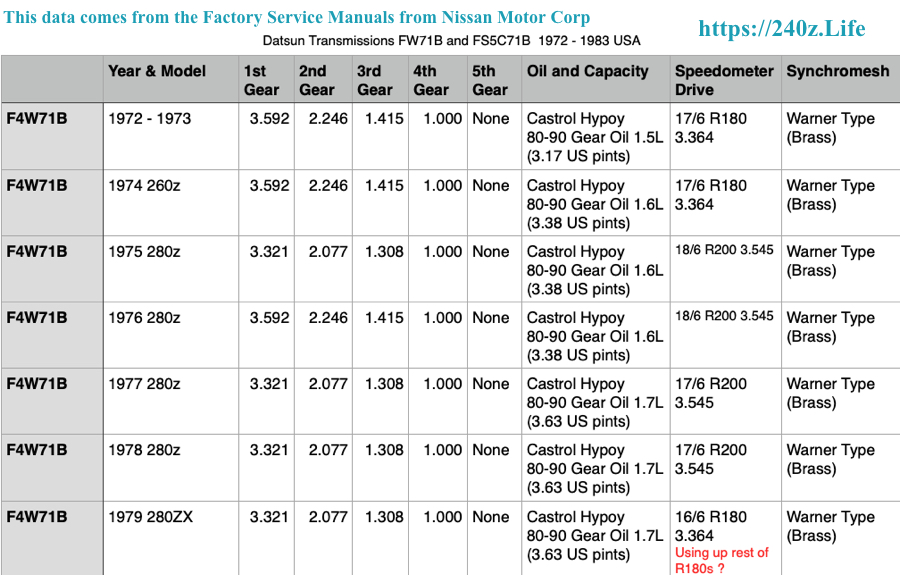

Datsun 4 speed manual transmission F4W71B Factory Service Manual Data

Year and Model, Gear Ratios, Oil and Capacity and Speedometer Drive Pinion Gear

The Datsun 5 speed manual transmission FS5W71B found in Datsun 280z and 280ZX

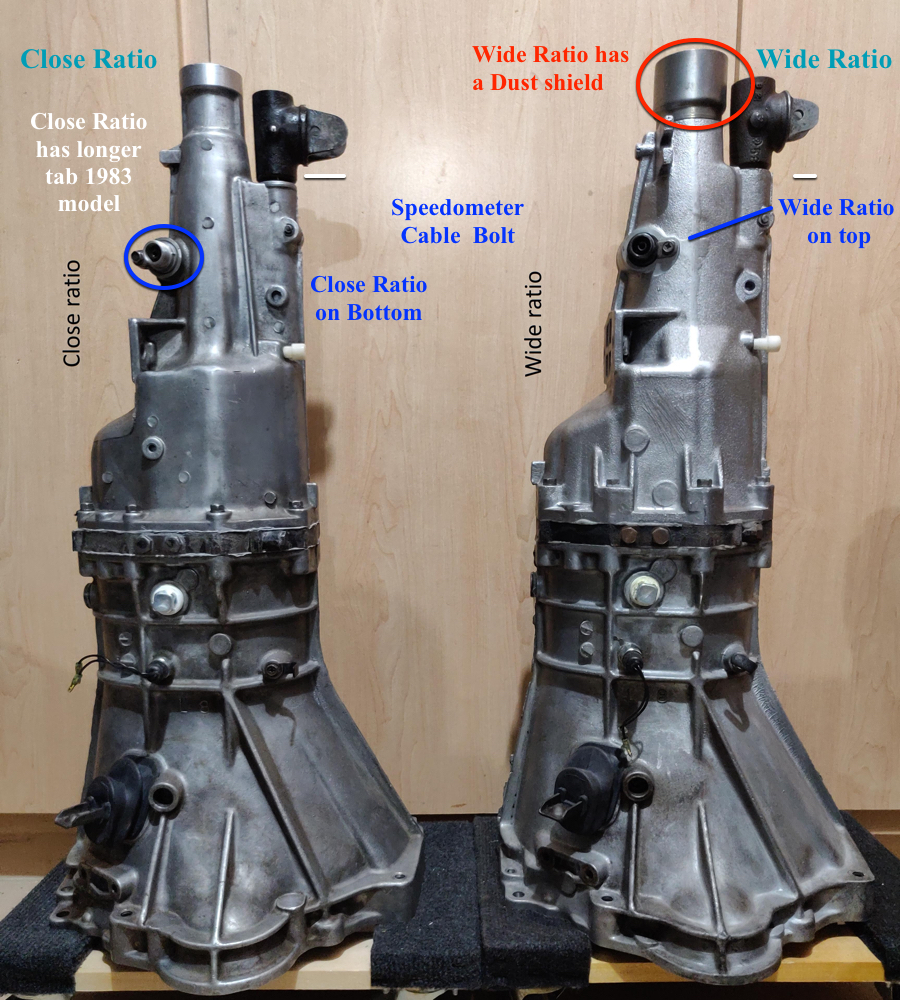

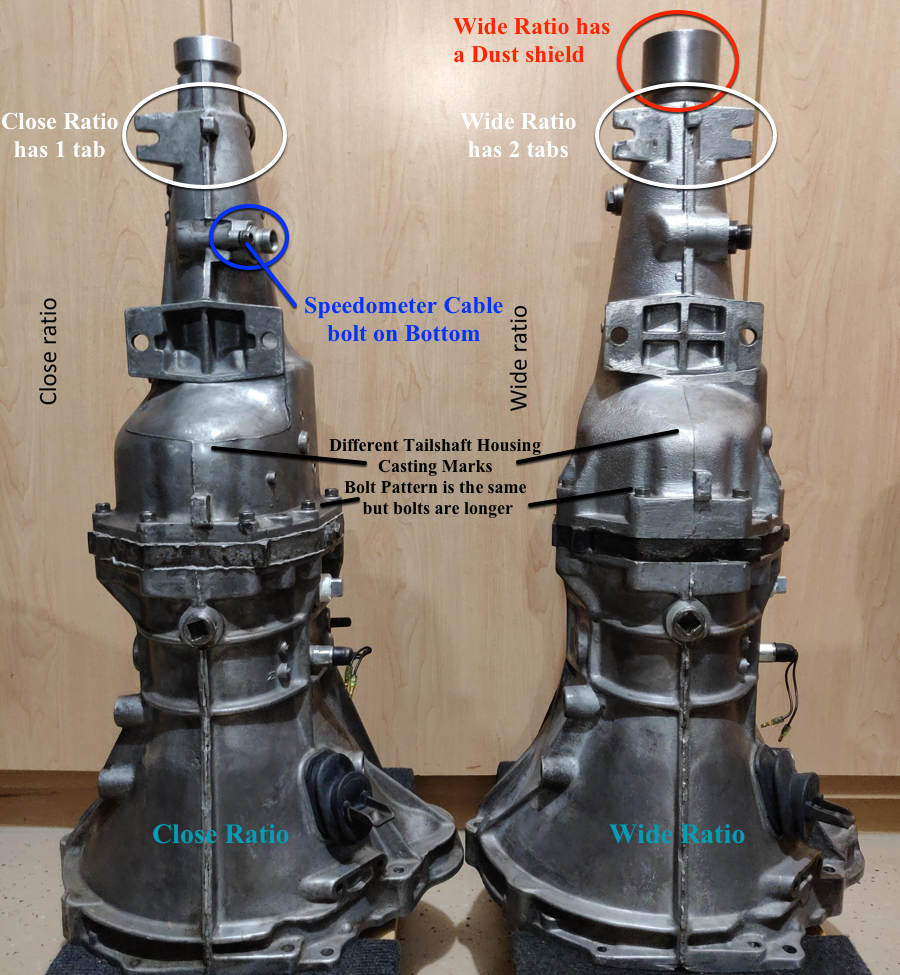

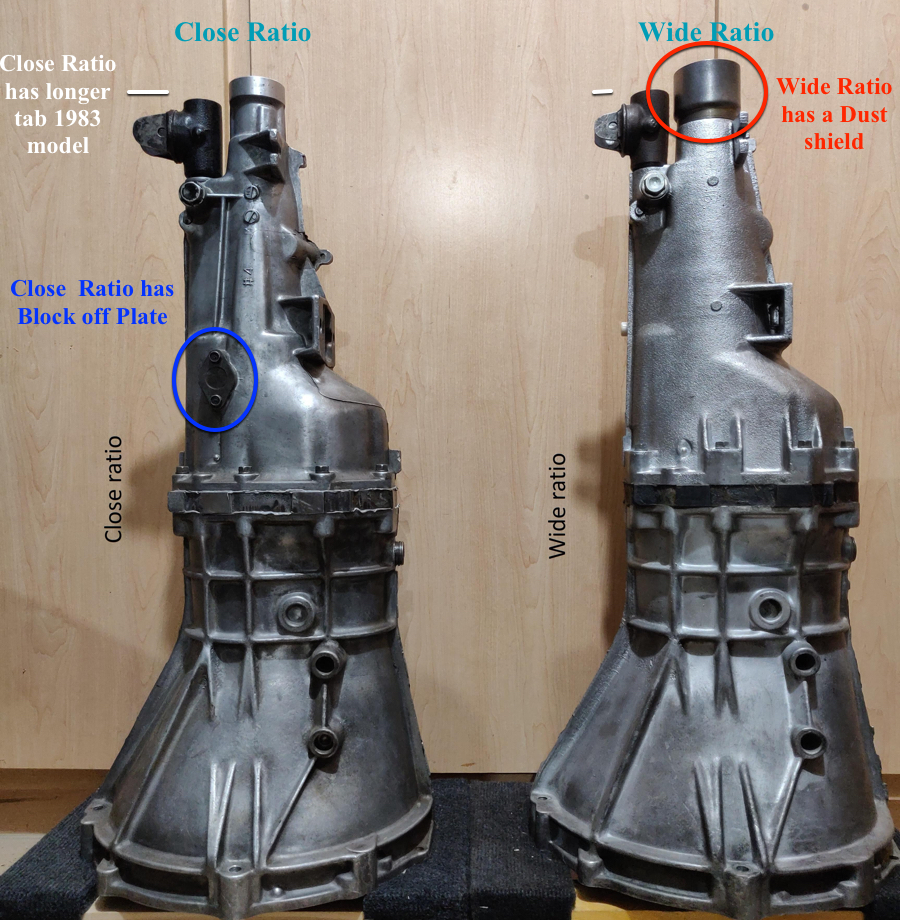

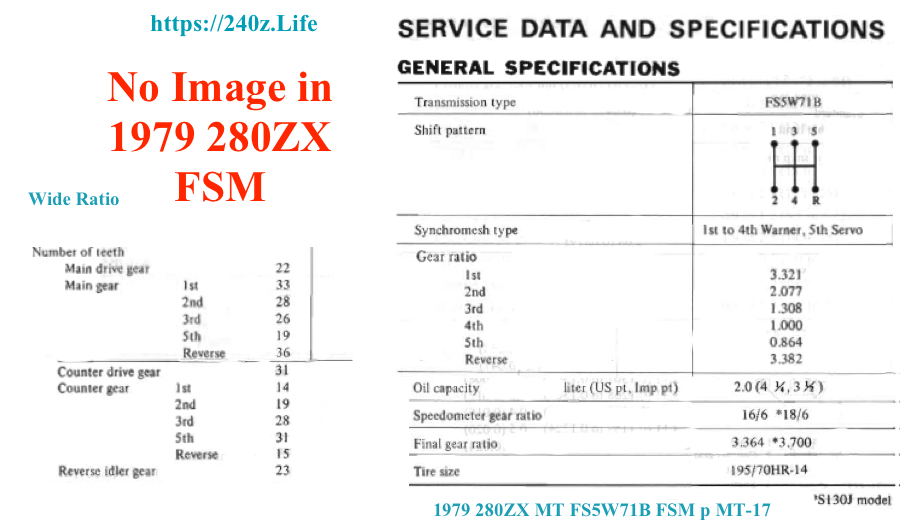

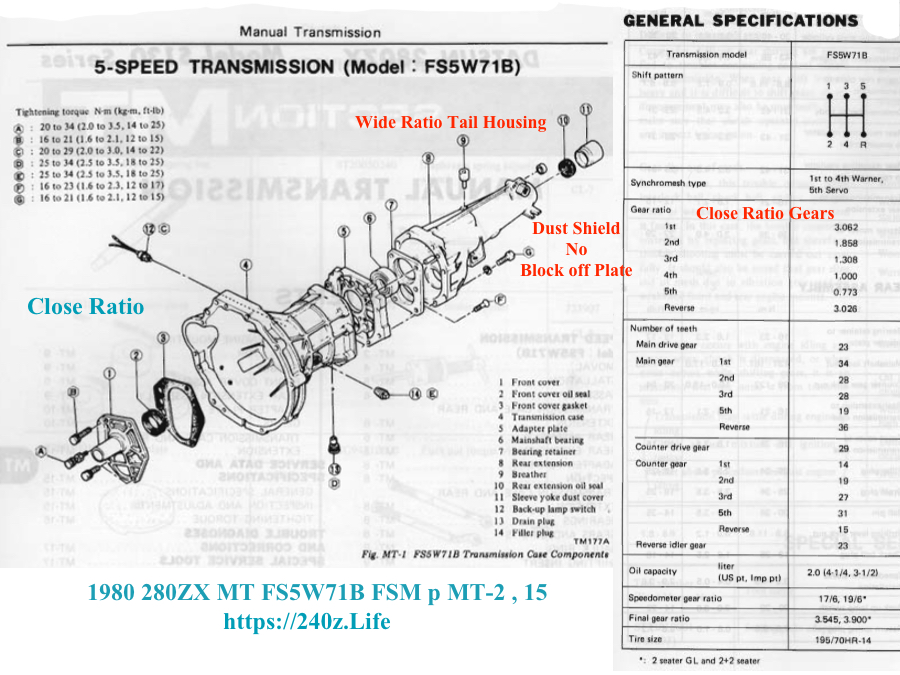

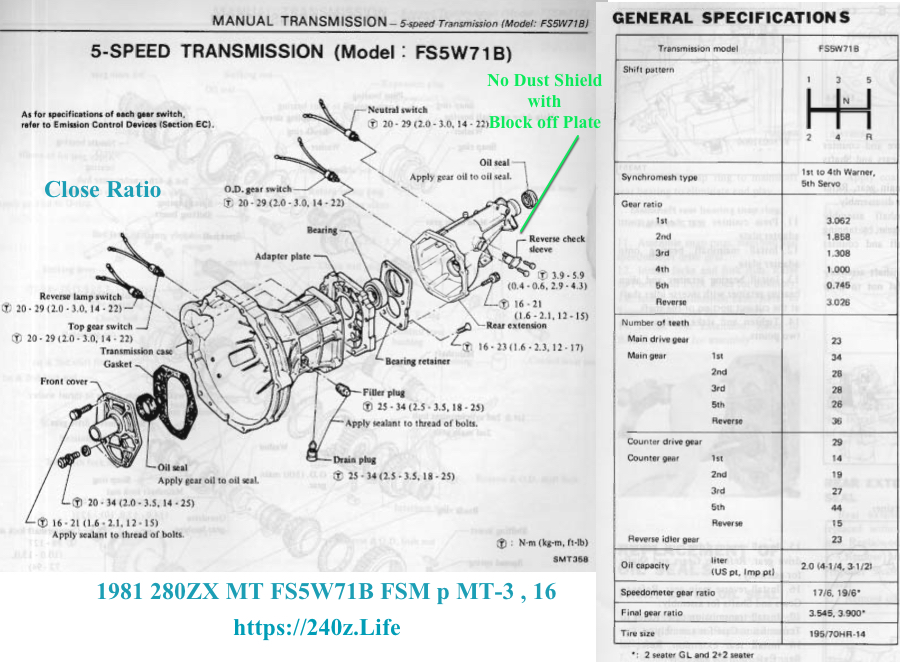

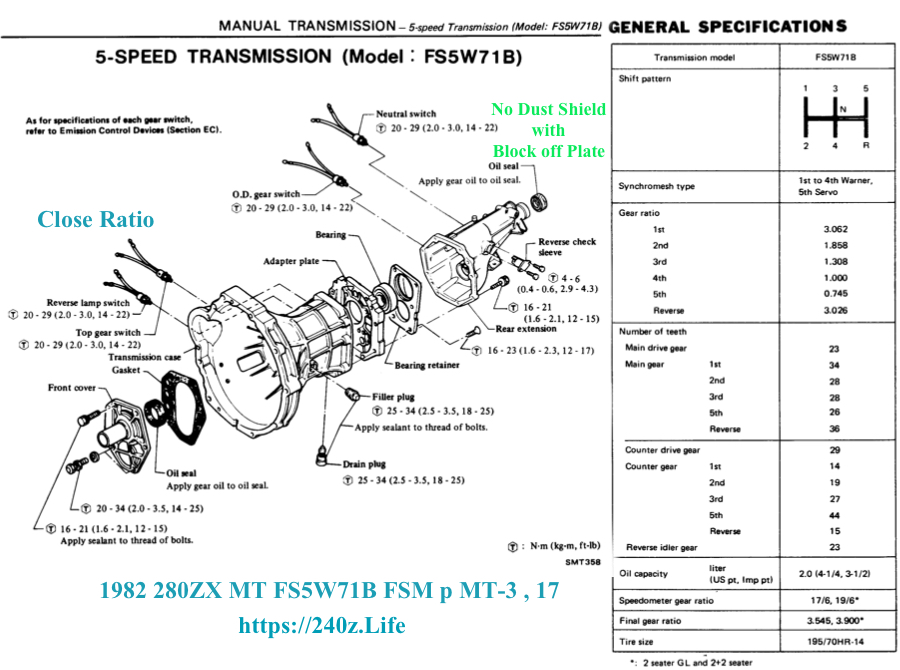

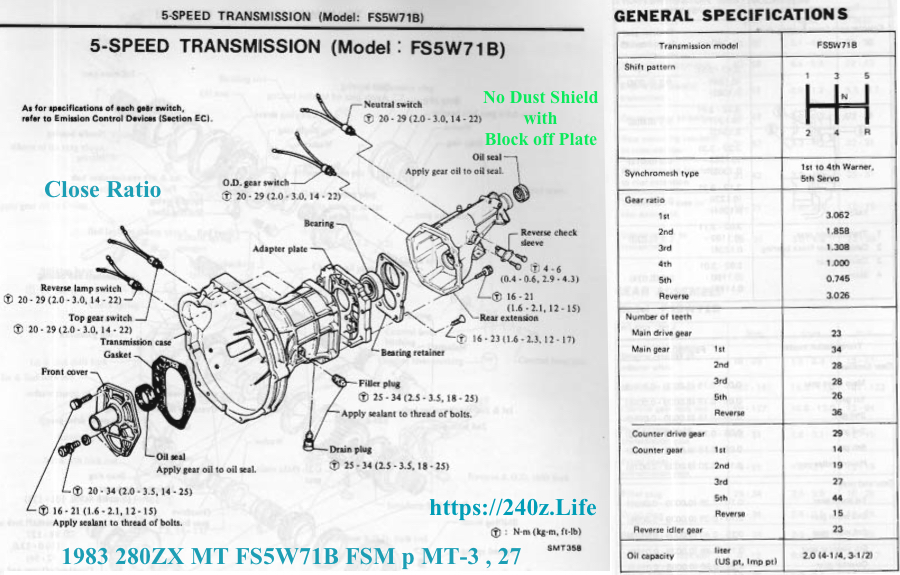

The 5 speed Manual Transmission designated as FS5C71B came with different gear ratios and tail housings. There is a “Wide Ratio” that was produced from 1977 – 1980 and “Close Ratio” that was produced from 1981-1983. You can tell the difference between these transmissions by looking at the tail housing.

I took a Transmission and Differential class, so I know a little about them. The gear ratio is determined by the output divided by the input. You actually count the teeth on the gears to do the math. The “Close Ratio” transmission is favored for the close gear ratios. If your racing, the closer the gear ratios are, when you shift your rpm drop is minimal. Looking at both transmissions gear ratios, the Close Ratio gear ratios are literally closer.

Differences between the Wide and Close Ratio FS5W71B 5 speed manual transmissions

There is some great info out there, I got these images from a post POGDEN made on https://www.classiczcars.com. and touched them up. The red, white, and blue (for USA) are the points mentioned in the article. The black text, are my observations from me looking at pics, may not be consistent. Would like feed back on , please.

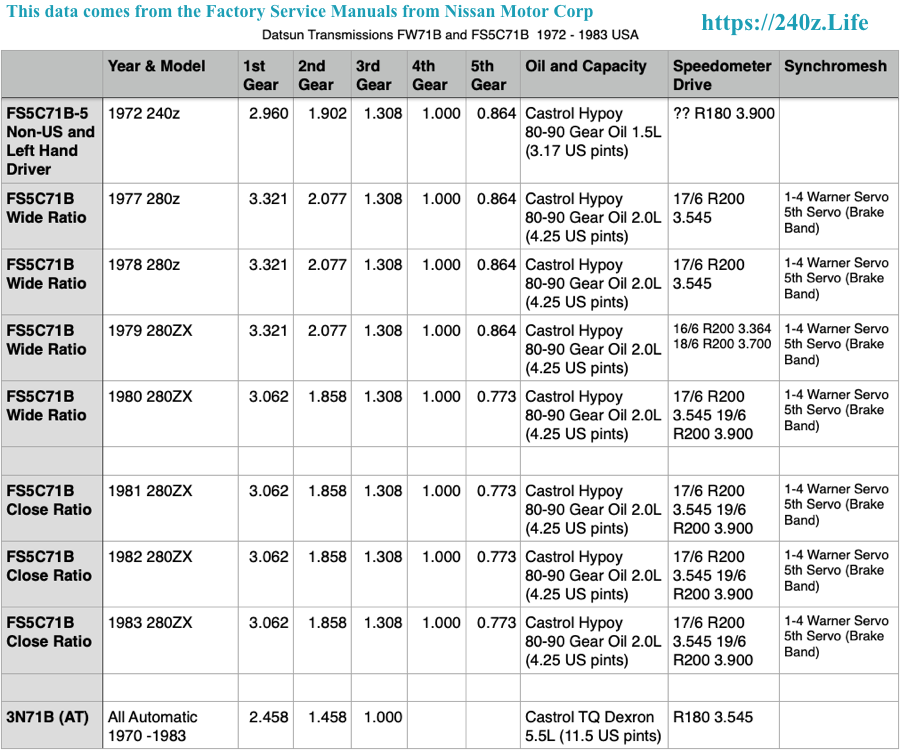

Datsun 5 speed manual transmission FS5C71B Factory Service Manual Data

Year and Model, Gear Ratios, Oil and Capacity and Speedometer Drive Pinion Gear

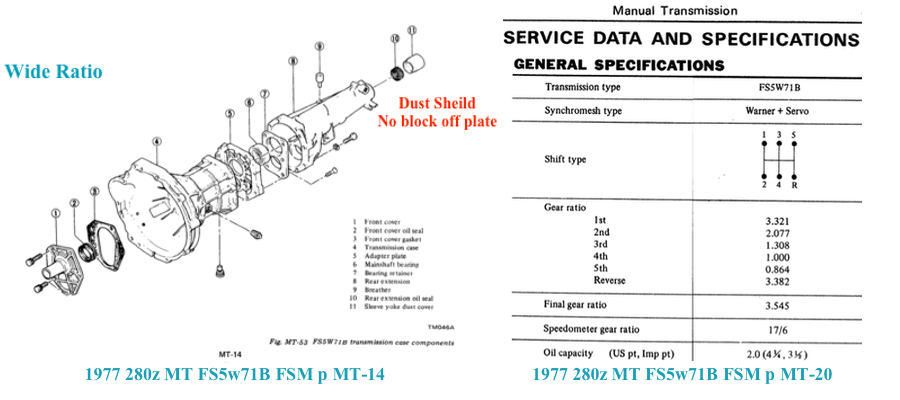

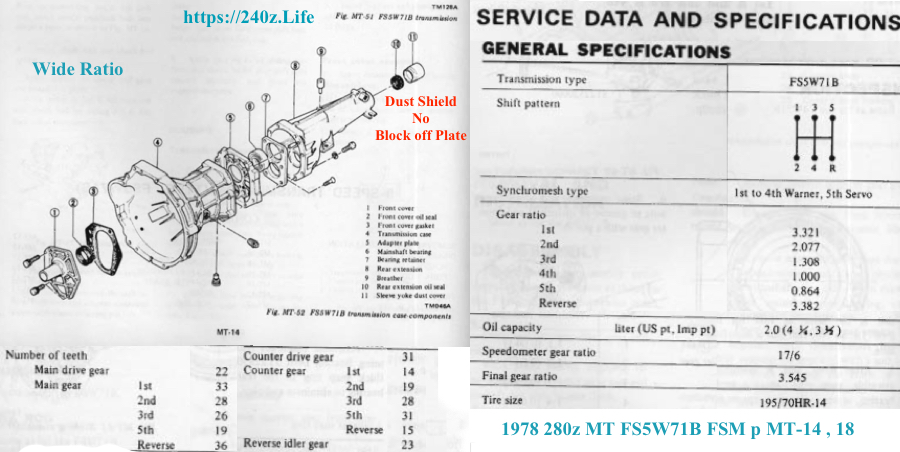

Images of FS5C71B for Identification purposes with Service Data and Specification

I created these images also from the Nissan Motor Corp. Factory Service Manuals, they have the gear ratios and teeth count for each gear. OK gear heads, lets see some mathematical calculations. I apologize for the images, some where photo copied. I am a Datsun 240z guy, and have forked out some serious $$$ for hard copies. Feel free to send me your Hard Copy FSM, I will digitize them properly.

I Thank You, for your efforts to keep this knowledge available to the masses for free. FSM manuals came from Xenon### (changed website name to XenonZcar.com) and https://www.classiczcars.com.

Thanks Again!

My Nissan Motor Corp Factory Service Manuals available on https://240z.Life Page

1980 FSM Wide Ratio Tail Housing, but it has Close Ratio gears.

Now here is a problem, possibly a misprint. I need some input on this guys. I did notice researching the differentials, that Nissan went back to installing the R180 in the 1979 280ZX, they switched to the R200 in 1975 280z. I believe they were using up the last of the R180s they had. Maybe in this year, they upgraded the gear ratios to the “Close Ratio” but used up the last of the rear tail housings for the “Wide Ratio”. The bolt pattern looks the same, but some bolts are longer because it is a different casting. Not sure.

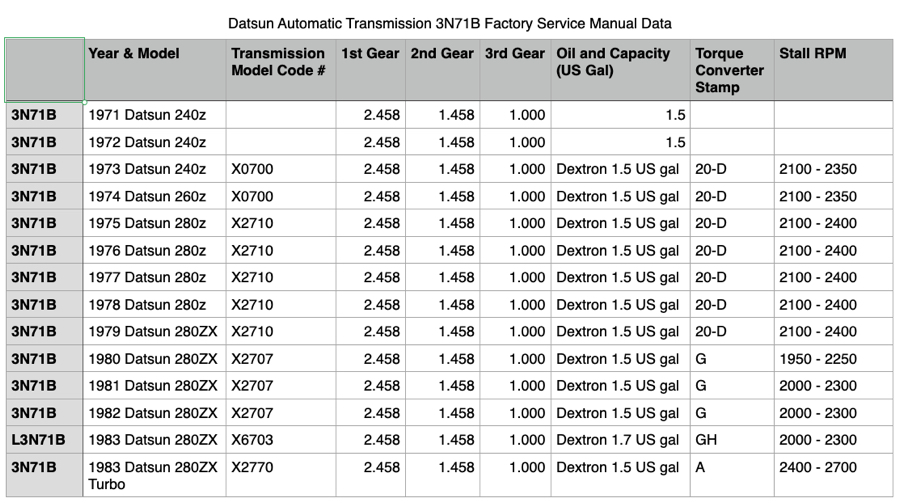

Datsun Automatic Transmission 3N71B 1971 – 1983 Datsun 240z 260z 280z 280ZX

The Datsun Automatic Transmission designated as 3N71B is the 2nd generation “B” automatic transmission, found in Datsun 240z 260z 280z 280ZX. There were 5 different models for this transmission. Below is a table I created to summarize the specs for the 5 different models. The changes were probably in the clutches ( number and material), the clearances and stall specs changed also. There were 4 different stamps on the torque converter, they were probably redesigned also. The differences could also be they changed the manufacturer of components.

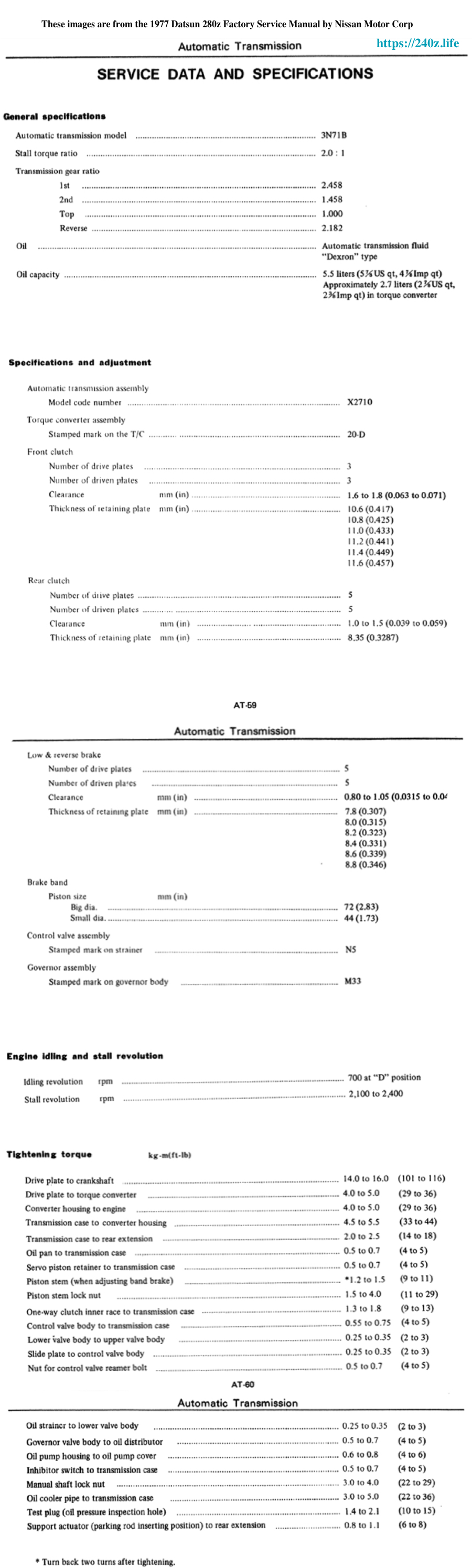

These images are from the 1977 Datsun 280z Factory Service Manual by Nissan Motor Corp

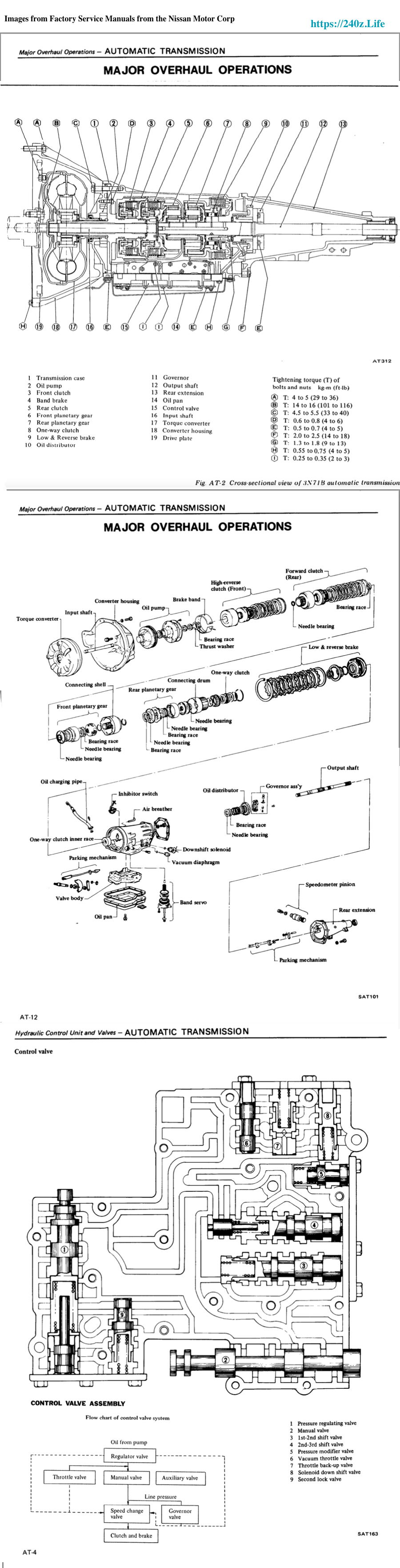

Images from the Automatic Transmission section, for the 3N71B transmission from the 1977 Datsun 280z and the 1982 Datsun 280ZX FSM. The 1980 Datsun 280ZX Factory Service Manual had the first Major Overhaul Procedure in it. If anyone has the FSM for the Jetco 3N71B Automatic Transmission please email me.

The internal workings for an automatic transmissions are completely different. There is an input and output shaft, but no counter shaft. The shifting is done with solenoids and control valves, based on fluid pressures. Check out the factory service manuals, there are diagrams and flow charts for shift points and data.

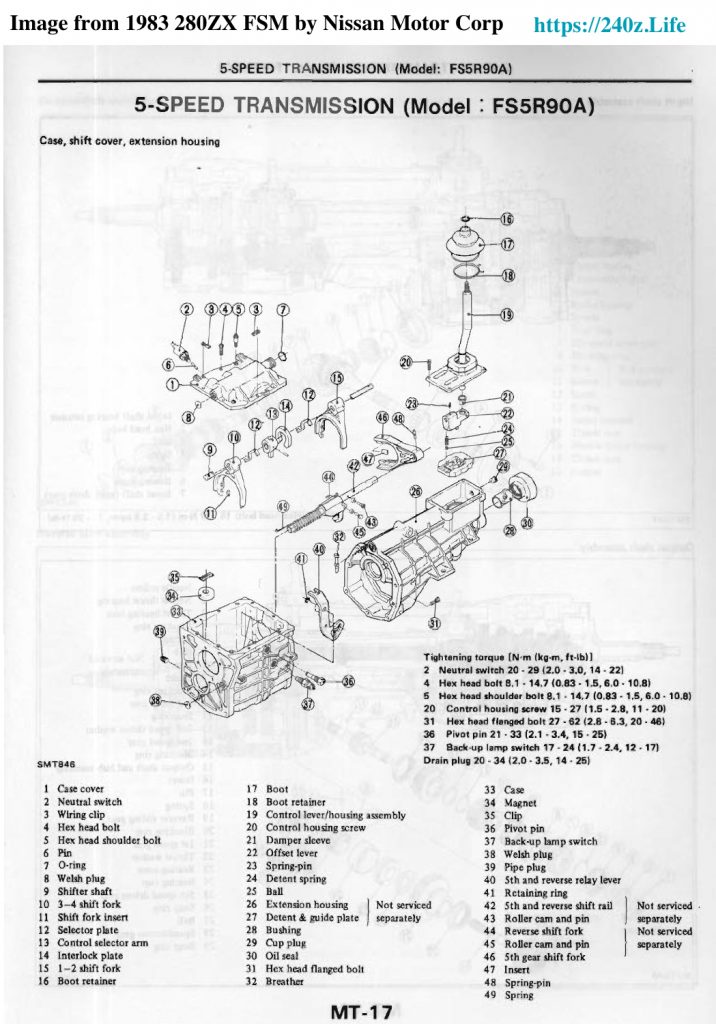

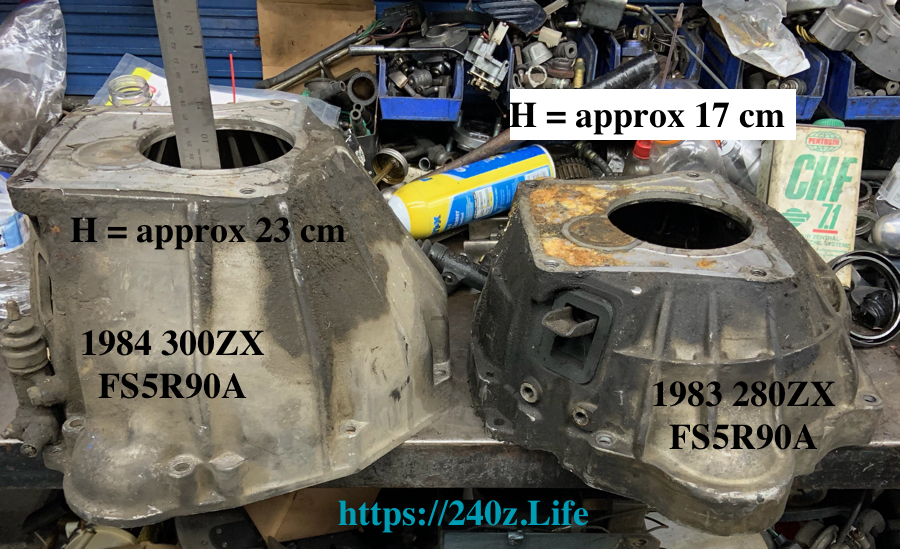

Borg Warner NWC T-5 Manual Transmission designated as FS5R90A

The 1983 Datsun 280ZX Turbo came with the Borg Warner NWC T-5 Manual Transmission designated as FS5R90A. This transmission is tougher than the FS5C71B.The increased horsepower with the new 2.8L Turbo motor, from 132 HP to 197 HP, required a beefier transmission. (L28ET : L28 = 2.8L E= Electronic Fuel Injection T= Turbo). The Borg Warner Non World Class transmission was designed to fit many car makes and models, by using a different bell housing. Most images leave the bell housing out.

The S30 and S31 models are different and are not compatible, the Input shaft is longer in the 300ZX FS5R90A. The Ford version of the Borg Warner T-5 NWC has a larger diameter output shaft.

These images are from Rod in California, Thanks Rod!!!

Manual Transmission Internals, Fluids, and Matching Differentials

How does a Manual Transmission Work?

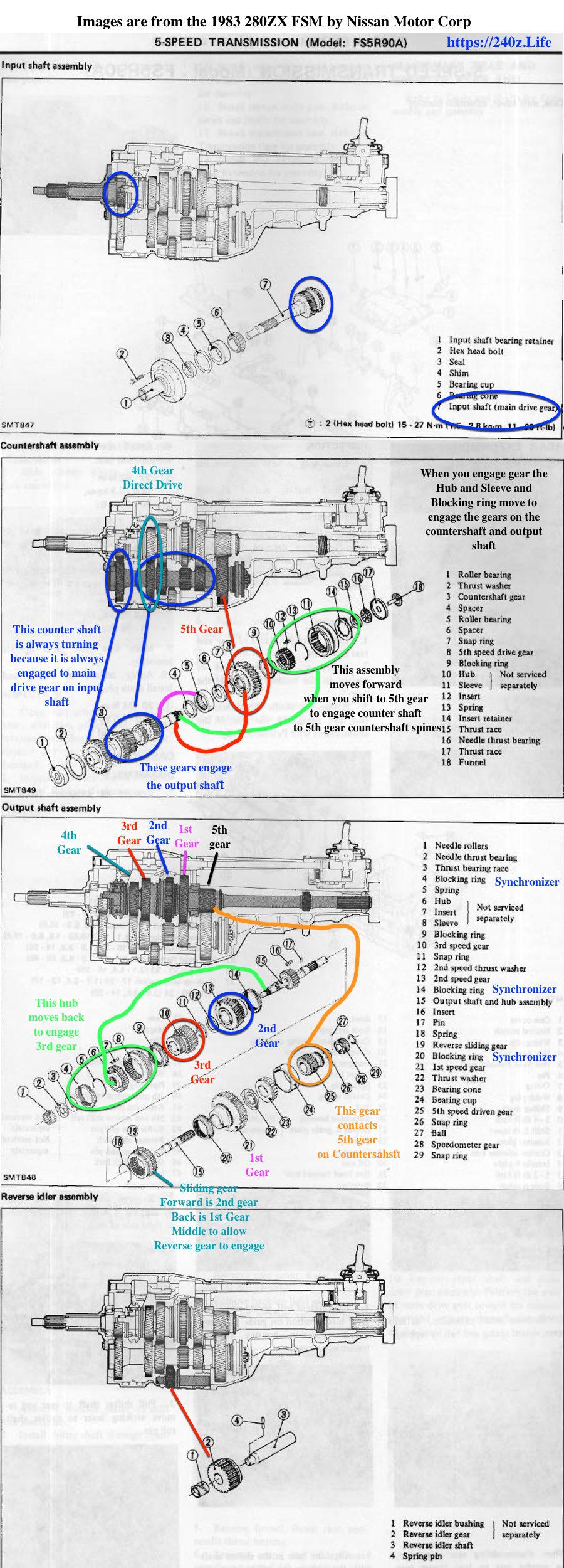

A manual transmission has 3 main shafts. The Input Shaft is the first shaft, this shaft has spines on it. The splines align the shaft with the clutch and pressure plate, and the front tip enters the “pilot bearing” installed in flywheel. The Counter shaft is what transfers the energy from the input shaft to the output shaft. The gear on the input shaft is what drives the countershaft. The output shaft is the shaft that leaves the rear of the housing, the driveshaft yoke slides onto this shaft and is aligned with splines. The Reverse Idle Assembly is the Reverse Gear. When you shift gears, synchronizers actually sync the speed of the gears that are about to engage, matching the rpm of the gears so when they engage they engage perfectly aligned. The synchros are made of a brass, a very soft material, if there is any wear due to shifting the brass synchros will wear and not the gears. As you shift the shift forks actuate the hub and sleeve which forces the gears to engage. Five speed Transmissions usually have 3 shift fork which move the sleeve and hub located between 1st and 2nd, 3rd and 4th, 5th and Reverse. Notice how your shift pattern goes from forward to back. In first gear the shift fork moves the hub snd sleeve (#10 in parts diagram above) is pushed forward to engage the 1st gear. When you are in neutral, the husband sleeve are in the center position. Shifting to 2nd gear moves the hub and sleeve and this engages 2nd gear. This is the same for 3rd and 4th shift hub and sleeve (#15 in parts diagram above), because the shift pattern is the same. The 5th gear and reverse shift fork/actuators (#46 in parts diagram above) work this way also. Notice how the gears get smaller as you go from 1st to 5th gear.

The distance travelled per revolution (circumference) is decreased as the diameter gets smaller, so your output rpm increases as the gear circumference is reduced. We travel more distance with 5th gear (gear ratio of .75), 1 rpm input (1/.75) turns the output shaft 1.33 If 1st gear ratios is 3, the input shaft makes 3 revolutions to 1 revolution of the output shaft. The higher gear ratio (1st) gear gives you more power / torque, you accelerate faster. Distance traveled of input shaft compared to the distance traveled by the output shaft is 1:3 You have more power to turn the wheels and accelerate. In 4th gear the ratio is 1:1 so the input and output shaft spin equally, in 5th gear the the output shaft (5th gear ratio .75) spins 1.33 times, Less power = more rpms. Gear ratios are always measured by teeth count output gear over teeth count input gear, the measurement of the distance between the gear teeth is the same for the 2 gears that are engaging, the spacing must be constant for gears to mesh properly. So by comparing the distance actually traveled, by counting the teeth, you see the ratio Output distance / Input Distance. If the output distance is larger, you lower your power to do work coming out, for more output distance. When driving you realize more power/torque at wheels, Input revolutions are higher than output revolutions, but distance traveled is less. Work = Force x Distance. So Force and Distance are inversely proportional. Force goes up Distance goes down, Force goes down Distance goes up. The math can get complicated with angular distances, but remember it is still a liner distance travelled (the circumference of the circle/gear). Calculating the “gear ratio”, it always output teeth / input teeth, The gear ratio is the product of all the gear ratios in the transmission that the energy is transferred by. [(Countershaft gear that contacts the Input shaft gear has a ratio of the # teeth on the countershaft gear / # teeth on the input shaft gear (Main Drive Gear)) * (# teeth on the gear on the output shaft, 1st, 2nd, 3rd, 4th or 5th) / (# of teeth on countershaft gear that contacts the output shaft)] . The differential gear ratio is easy to calculate Output / Input, # of teeth on the ring gear / # of teeth on the pinion gear).

Below is an image I created from the 1983 Datsun 280ZX Factory Service Manual by Nissan Motor Corp, to show the internal workings of the Borg Warner T-5 Non World Class Transmission in the 1983 280ZX Turbo Model. I think I got it right. Let me know guys! Its difficult to interpret the drawings, but having a live working model would’ve helped. Just remember the gears diameters decrease from 1st to 5th gear on the output shaft. There will be a synchronizer/blocking ring next to the gears, these align the gears when they engage. Gears that engage will have opposite hatch marks on them if they are at an angle.

What transmissions go with which differentials?

I installed a 4.38 R180 from a Subaru with my 4 speed F4W71A. The top speed was really low. I think I was at 4000 rpm doing 60 mph. Well I dont know my exact speed, the purple gear on the speedometer was not installed. Be sure to check out my speedometer pinion chart. I decided, much like Nissan, I need an over drive gear. I installed a 5 speed the FS5C71B Wide Ratio. In the Series 1 240z, because of the redesign of the center console and different length transmissions, you will need to cut about an inch from the top part where the shifter is for shifting clearances. To move the shifter arm backwards a few inches, I cut my shifter and welded in about a 2.5″ section of bar stock. I will post that with pics. There are shifters you can buy that have a bend in it that moves the stick shift to the rear of the car, they are hard to find and pricey. I had so much torque with the rear end, I could’ve towed a semi truck with a full load. It would peel the tires off , chirp 2nd, and 3rd. I eventually decided to install the stock rear end, a 3.364 ratio for street use.

Lesson to learn, Nissan designed the transmissions and the gear ratios to go with the specific rear end ratio that came with the car. They engineered it perfect! If you want overdrive for highway use then definitely upgrade to the 5 speed FS5C71B. If you are racing, Great!!! …go with the Close Ratio. They are getting hard to find, so a Wide Ratio will work also. You can also re-gear your rear end. If your a serious racer, you probably have different Ring and Pinion gears and have several transmissions also, with custom cut gears for your optimal shift points for different track situations. I would love to talk to some real racers and pick their brain… What transmission and differential gear ratios do you use for each track you race on. Can I get a List, please.

The function of the fluid in a transmission, fluid weight “Viscosity” and Temperature

The gears mesh with clearances, so there is no gear to gear contact, the transmission fluid is what touches the gears, remember fluid is not compressible, so the forces are transferred. The clearances are based on the fluid characteristic know as Viscosity. The “weight” of the oil is a measure of the fluids viscosity. I took Fluid Dynamics at the University of Florida while pursuing my Engineering Degree, Go Gators! I had a lab assignment where we measured viscosity of different liquids. The apparatus was a container with veins attached to gears, like 4 paddle wheels attached to a shaft that had a set of gears attached to it, and a pullet with a string and weight attached to it..

You would activate the device, a weight attached to a cable would go from Point A to B Vertically. We measured the time it took for the weight to travel from port A to B. The forces involved were gravity and the resistance of the fluid forces against the paddle wheels. Of course we had formulas to plug and chug and numbers to graph for determining the viscosity “weight of the oil”. The thicker the fluid the lower “weight”, low viscosity. Viscosity is defined as a quantity expressing the magnitude of internal friction, as measured by the force per unit area resisting a flow in which parallel layers unit distance apart have unit speed relative to one another. As temperature goes up, viscosity increases. The frictional forces cause the fluid temperature to increase, to keep the fluid from becoming to viscous and breaking down, it is cooled in a separate section of the radiator. The difference between gear oil (use GL-4 not Gl-5) and Automatic Transmission (use Dextron) fluid, the AT fluid has detergents and conditioners added to it. Always use the exact fluid recommended and the procedure to fill and measure the correct levels and change fluid at correct intervals. Dark fluid is dirty fluid. The plugs used in the Datsun Transmissions before the FSR90A have tapered plugs. Do not over tighten, you can crack the case, always torque to specs.