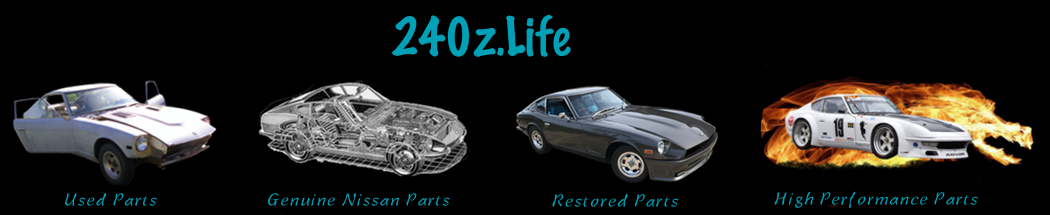

The Differential transfers energy from the propeller/ drive shaft to the side half axles. The propeller / driveshaft turns the Pinion gear which drives the Ring Gear, which transfers energy to the side gears. The half axles / driveshaft mesh with the side gears and transfer power to the wheels. All shafts use u-joints to compensate for the angles. Its important to measure the angles of the driveshaft and ensure consistency so the U-Joints last. An angular gauge with magnet is used, you simply measure angles at both ends. They should be the the same, adjustment is done by adjusting the height of the transmission mount. There were at least 8 different drive shafts, varying in length and diameter for the various models based on Transmission type, 2 Seater and 2+2 Seater, Non-Turbo and Turbo models. There is no info on the specs for the early 240z driveshafts.

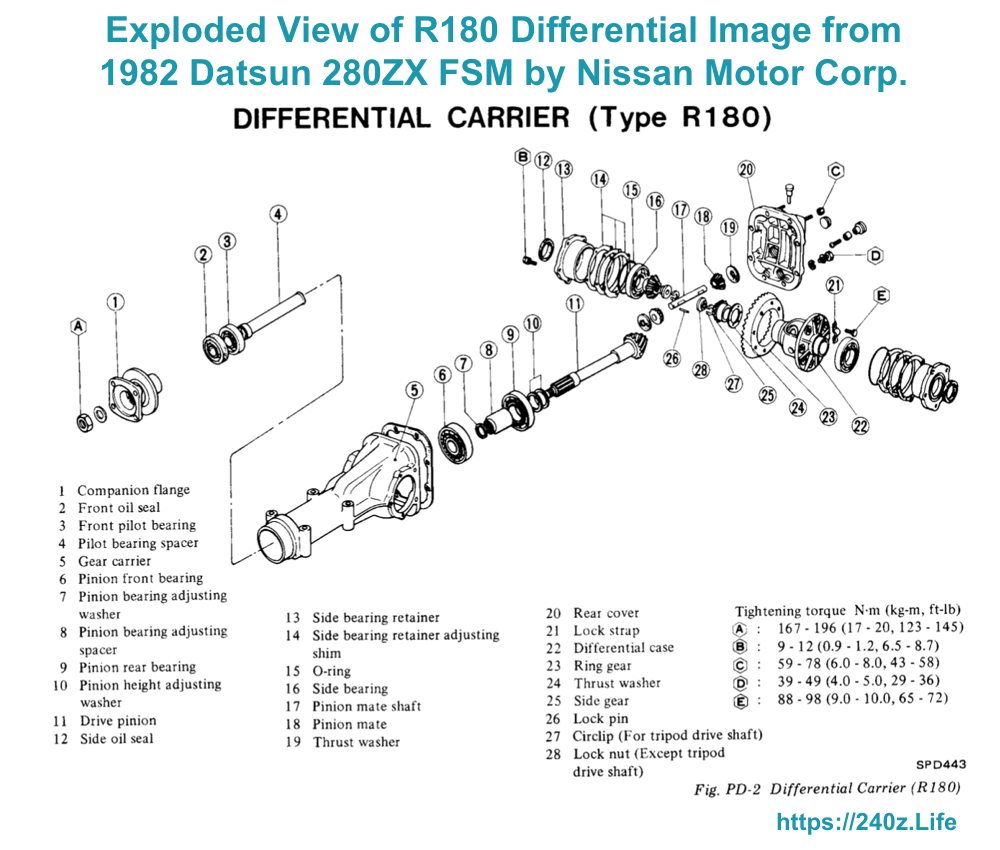

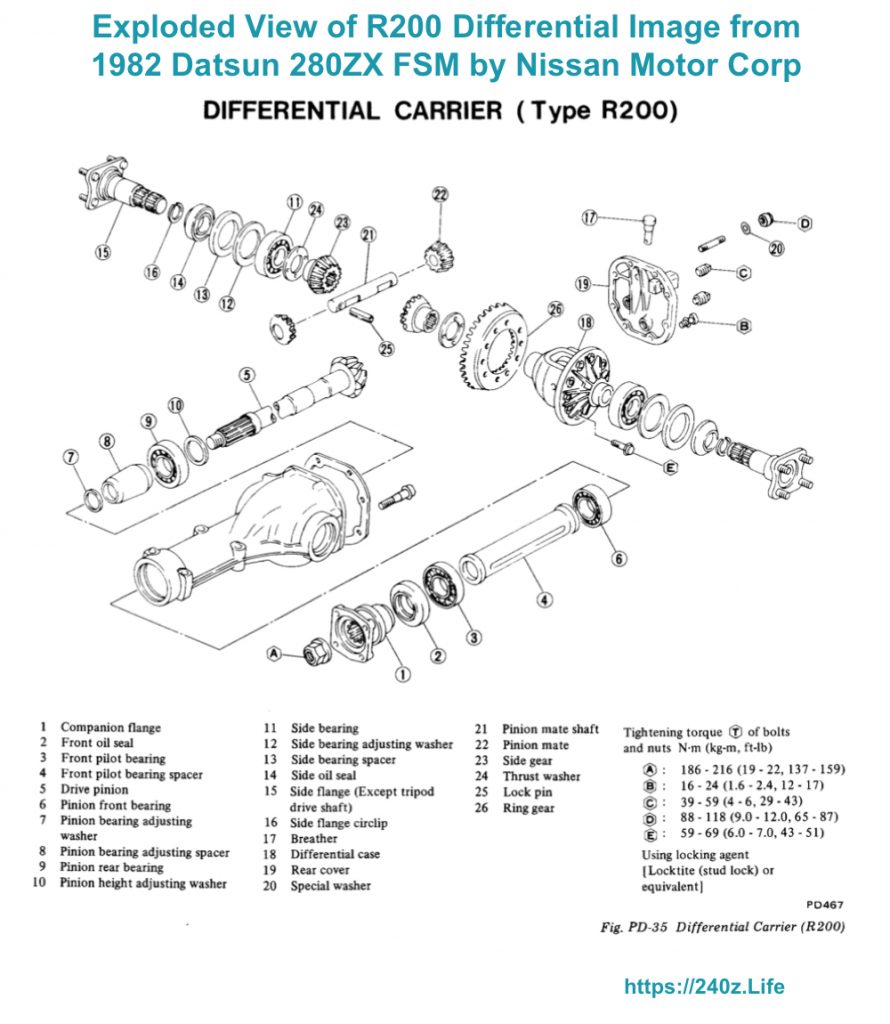

The differential design is required because the distance travelled by each wheel is different when turning, each wheel must rotate independently. The R180 and R200 “Open” differentials are pretty straight forward. Later differential designs, such as the Limited Slip Differential Design has a type of “clutch pack” that transfers the energy to the axels to minimize power loss. I took a rear end and differential class at Florida State College of Jacksonville, the designs can get quite complicated. Im not an expert at rebuilding differentials, but have experience. There is a lot of math involved to ensure proper alignment of all the gears. The gears must mesh together with proper clearances, they need to be precise! The clearances are based on the fluid used, viscosity and molecular cohesion factors determine the actual clearances. The gears never touch, they would wear! All the forces are transferred by the gear oil, fluids are non-compressible and transfer energy efficiently. The Datsun differentials have Hypoid Gears, the teeth of the gears are specially cut / designed to transfer extreme pressure, and use Hypoid Gear Oil API Gl-5. This fluid is engineered specifically for Hypoid Gears and is also used in transmissions. It has additives to protect the gears.

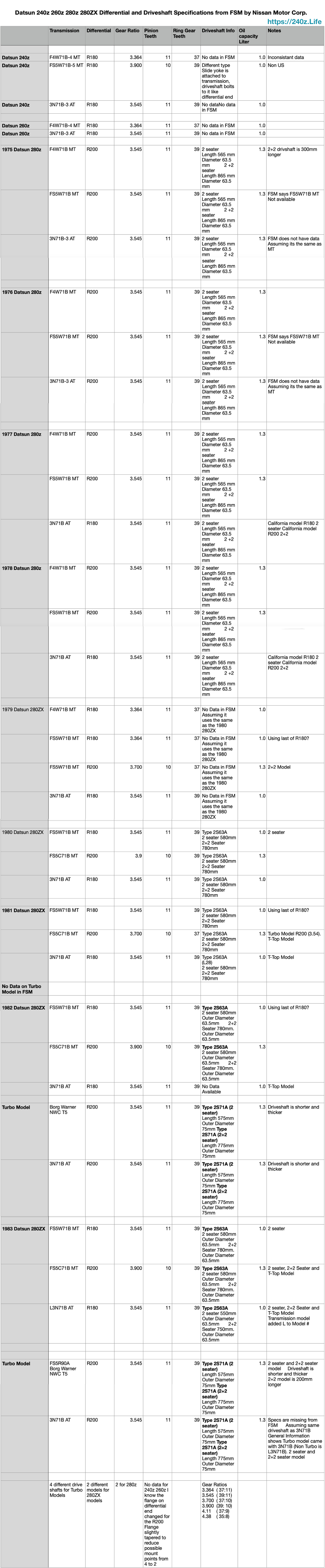

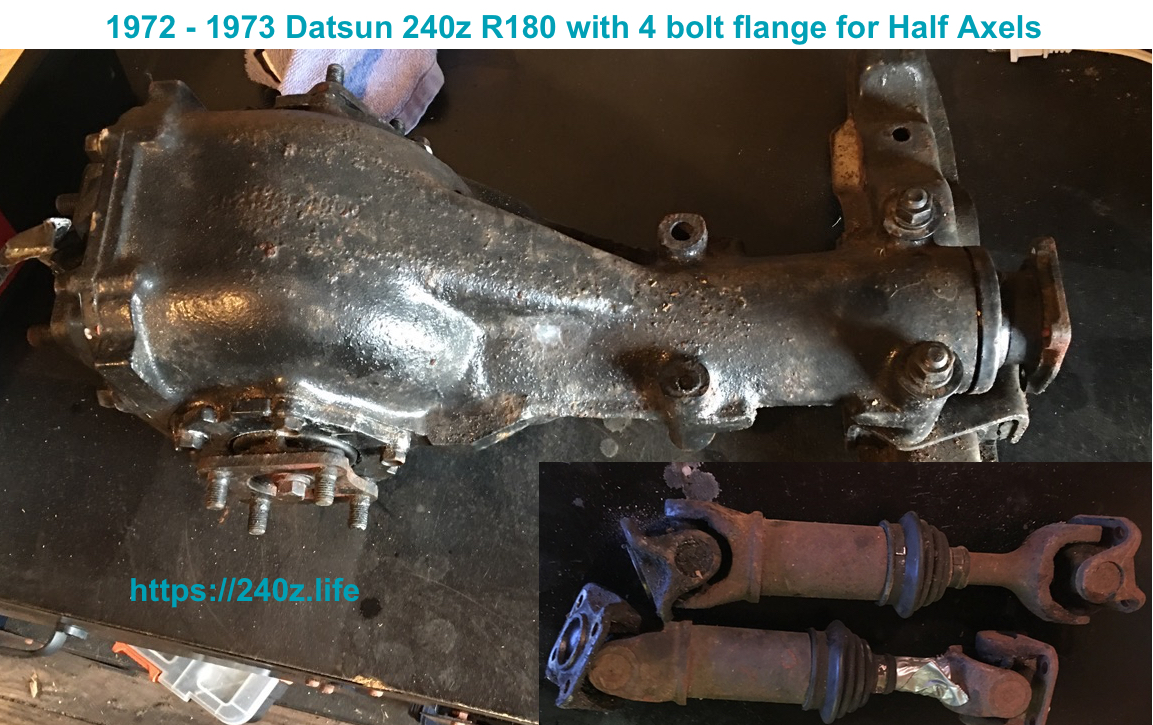

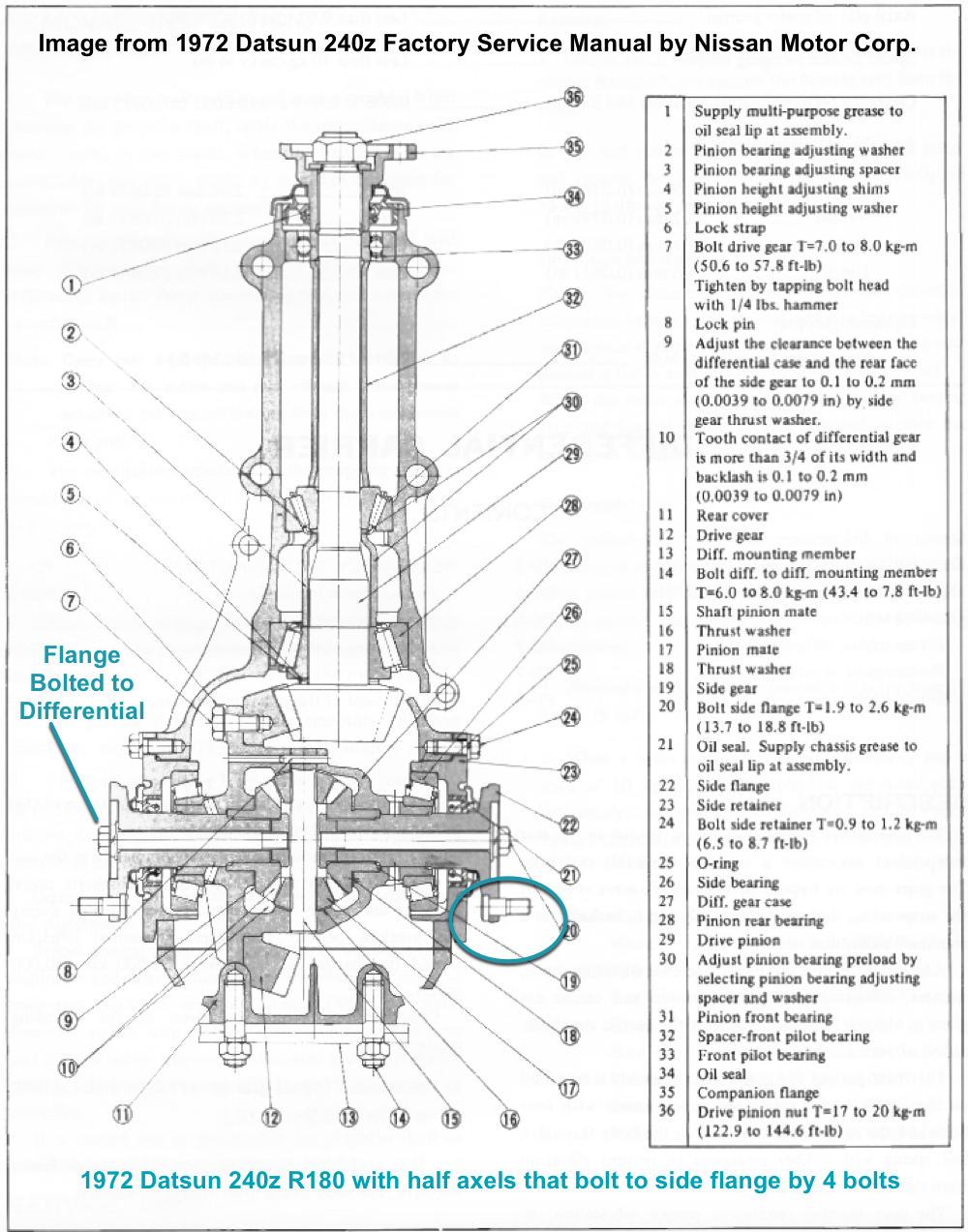

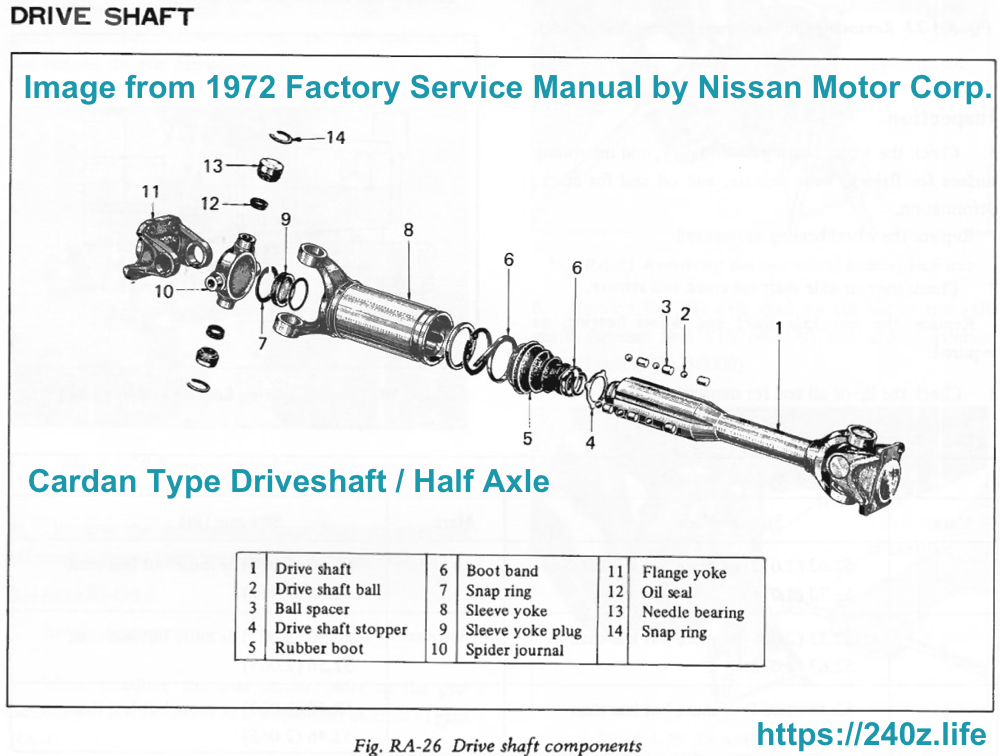

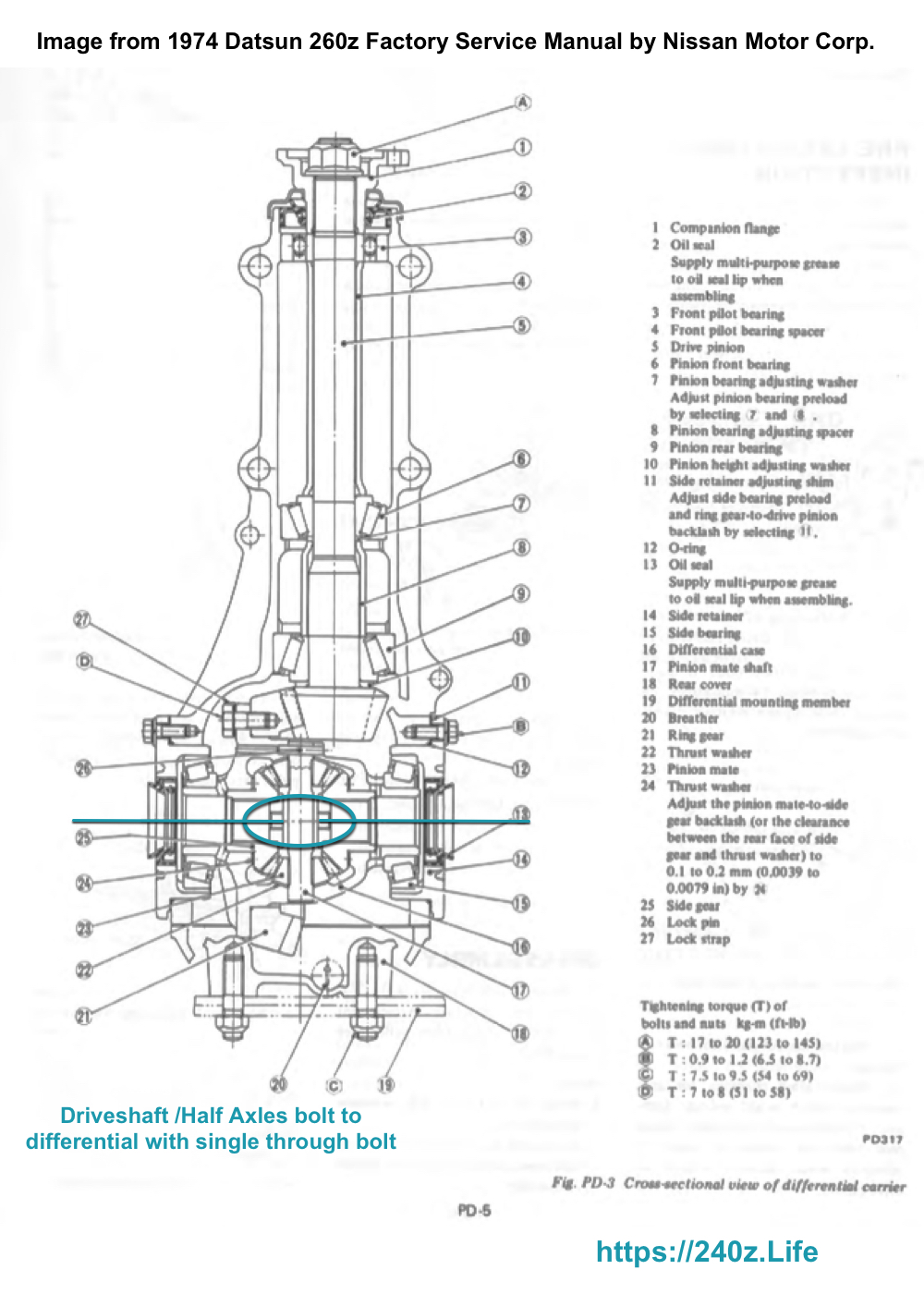

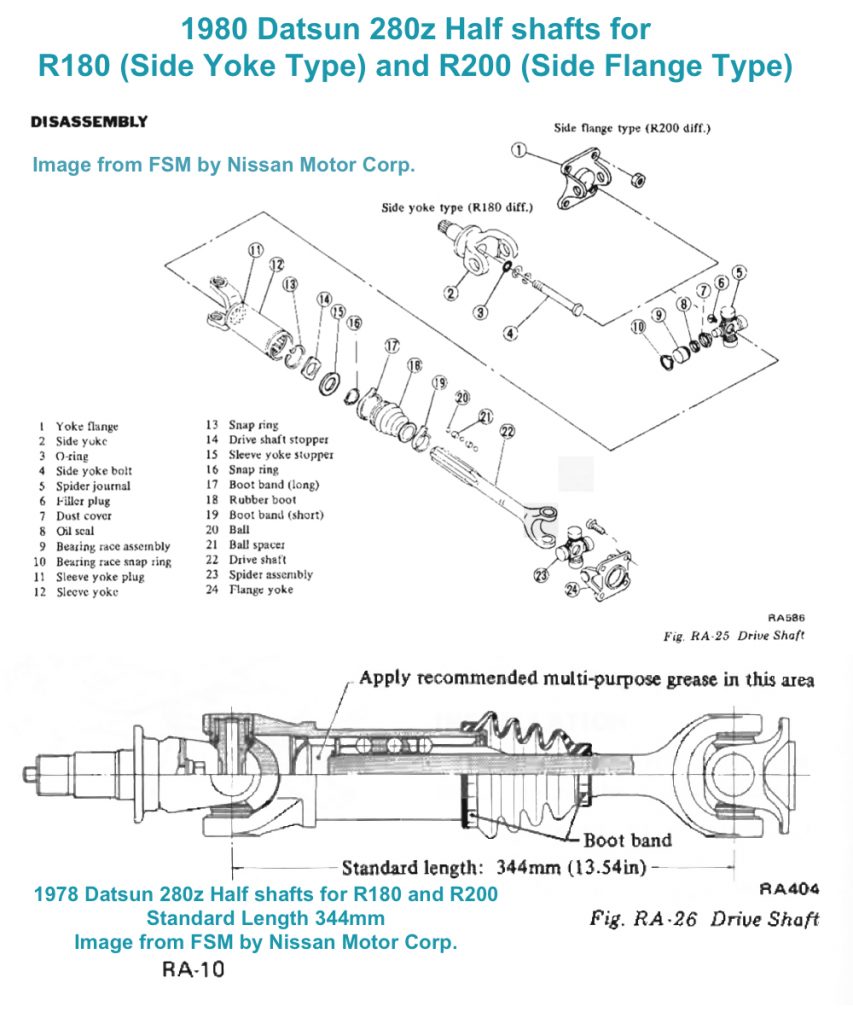

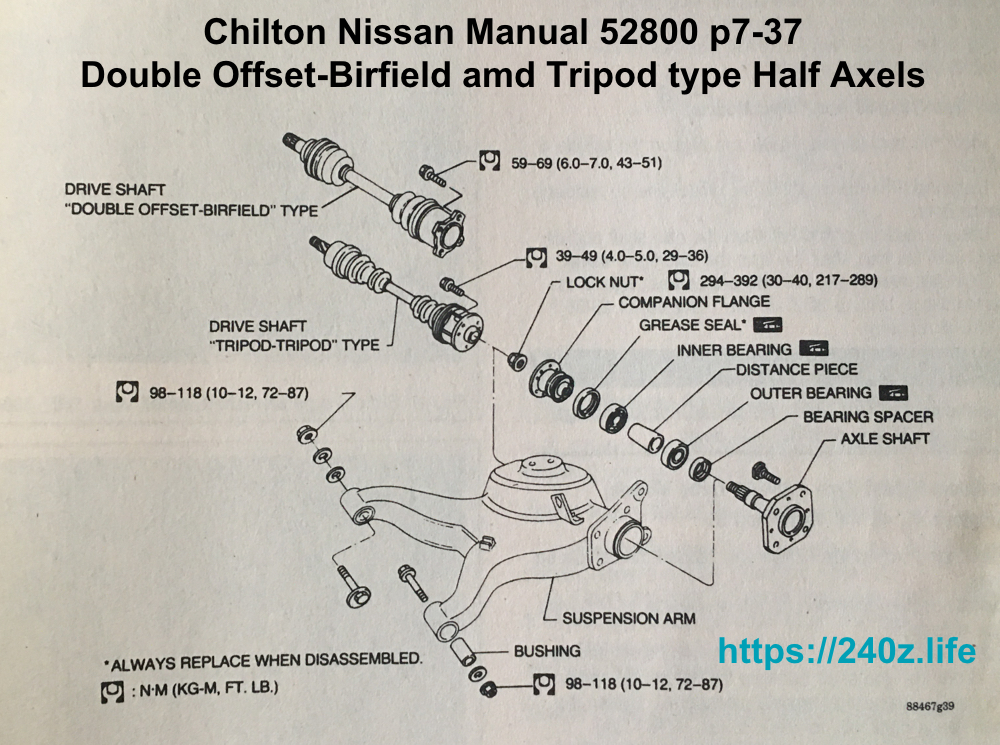

The 1970 – 1971 Datsun 240z came with the R180 differential, with the Half Axles that just slid into the side. The 1972 and 1973 Datsun 240z came with the R180, with the Half Axels that bolted to a flange by 4 bolts, that was part of the differential. The 1974 260z came with the R180 differential, with the Half axels that actually had a center bolt built into the side yoke. These axels are removed by removing this single bolt on the differential side. The 1975 – 1976 280z came with the new R200 differential. The R180 differential had a ring gear diameter of 180mm, the R200 has a 200mm diameter ring gear. The R200 is much stronger, the pumpkin end is much larger than the R180. The Factory Service Manual for the 1977 -1978 280z shows the R180 was installed with the models equipped with the automatic transmission, manual transmission models came with the R200. The 1979 – 1983 Datsun 280ZX came with several different Gear Ratios for the R180 and R200 differentials. The half shafts for 1970 – 1983 Non-turbo models are of the “Cardan” type. The Datsun 280ZX Turbo models had stronger Half Axels, known as the “Tripod Axel” type. The 1984 – 1988 Non-turbo models came with the “Double Offset-Birfield Type. This additional Half shaft info is from the Chilton Nissan Repair Manual #52800. There is not much info in the Factory Service Manuals about the Turbo models, perhaps for secrecy! Below are the Specs and Diagrams from the Factory Service Manuals by Nissan Motor Corp, followed by pics.

Datsun 240z 260z 280z 280ZX Differential and Driveshaft Specifications from FSM by Nissan Motor Corp.

Image from my archives Motorsport Catalog of R180 and R200 Ring and Pinion Gear sets

1970 – 1971 Datsun 240z R180 with Slide in Axels 4:38 Gear Ratio

1972-1973 Datsun 240z R180 with Bolt on Axles the Flange is bolted to Differential

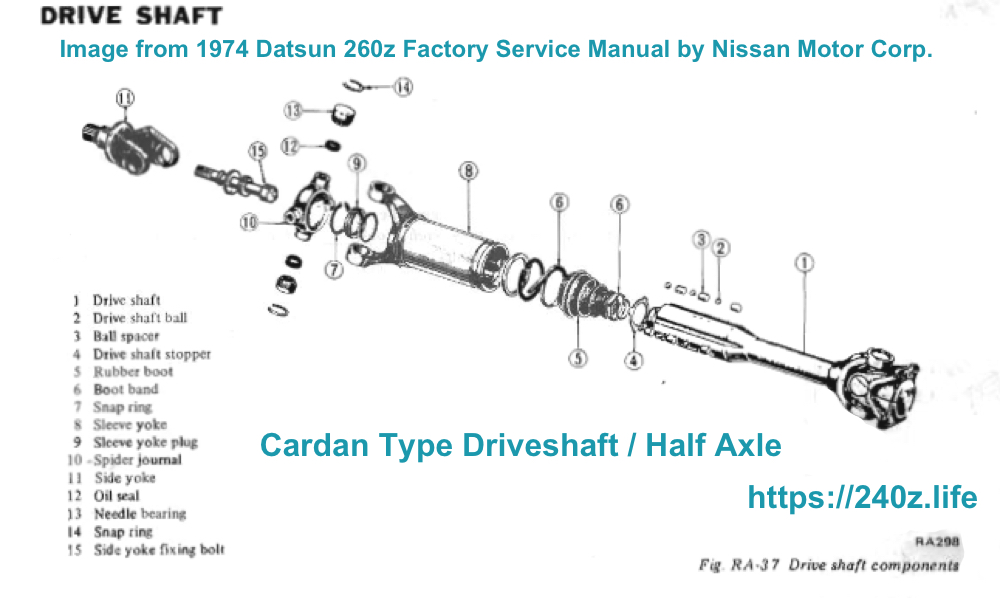

1974 Datsun 260z R180 with Half Shafts that bolt to differential with 1 large bolt

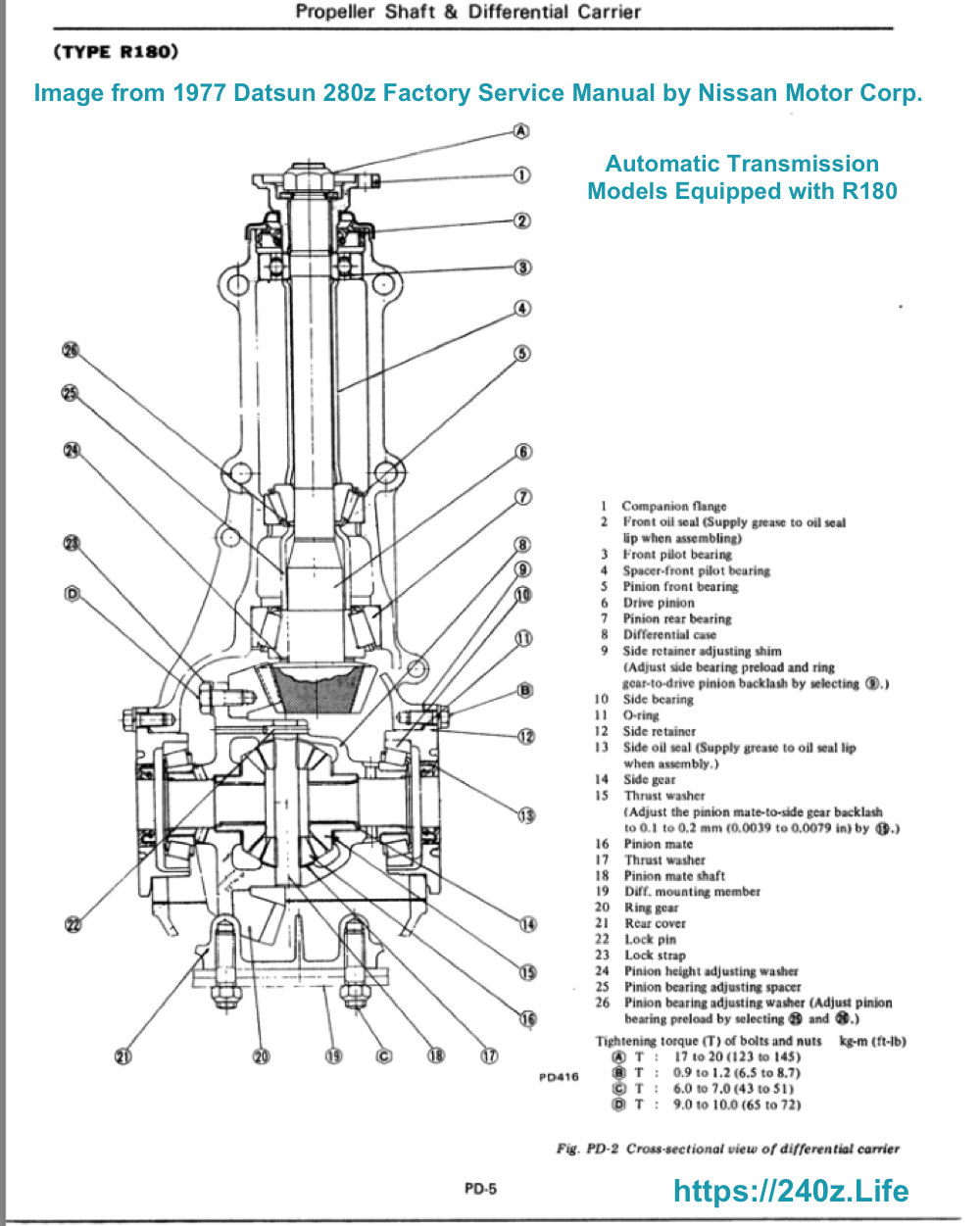

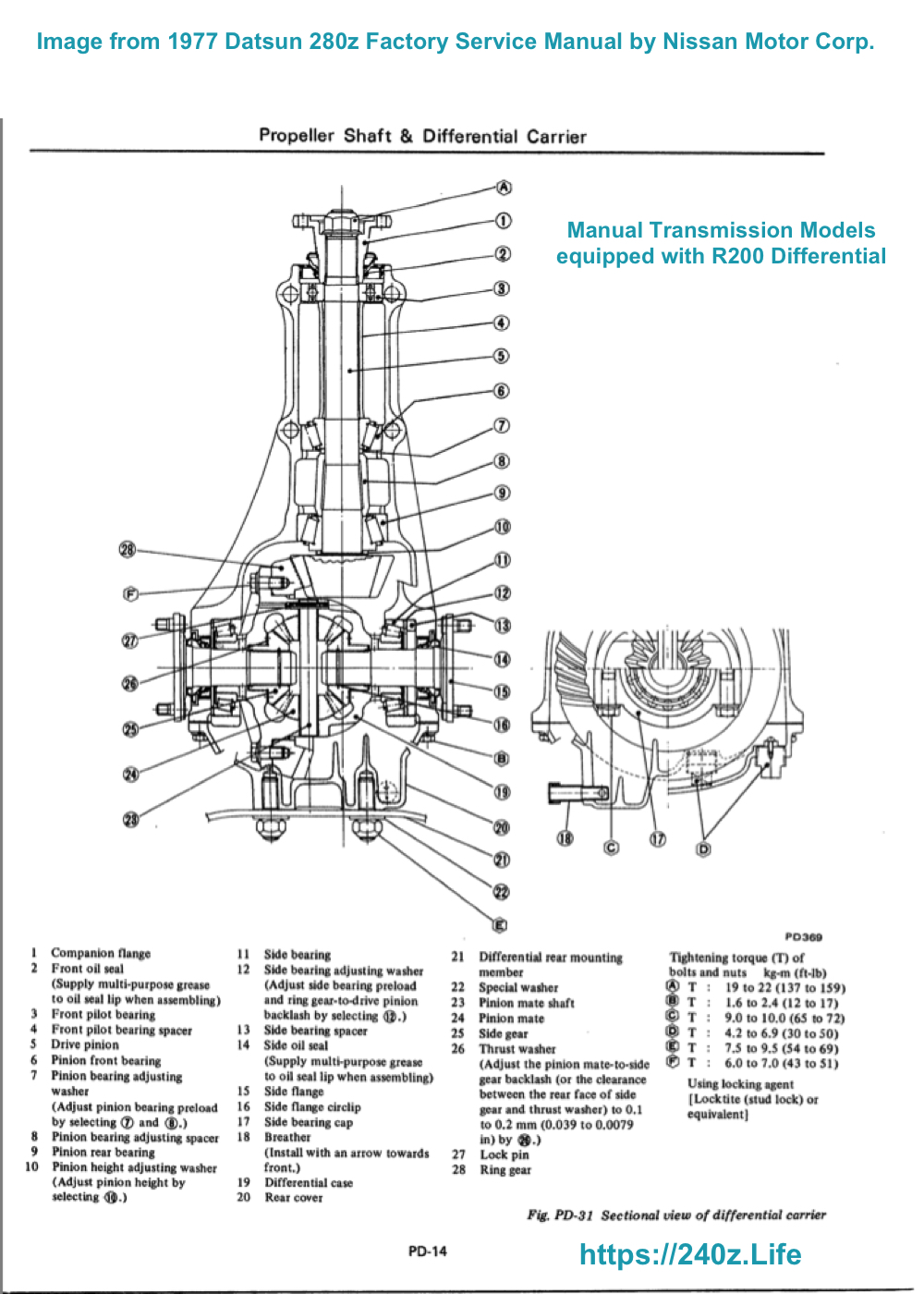

1975 – 1978 Datsun 280z R180 and R200 Differential

The Factory Service manual has no data on the transmissions used in 1975 -1976 Datsun 280z, it states all models had the new R200 differential. The 1977 and 1978 FSM by Nissan Motor Corp., state the models with Automatic Transmissions were fitted with R180, the manual transmission models came with the new beefier R200.

1979-1983 Datsun 280ZX R180 and R200 Differentials

There were a variety of gear ratios for the 280ZX, they used the R180 and the R200 Differentials. Please see spreadsheet for all the combinations. I think they were trying to use up all of the R180’s they had.

The Datsun 280ZX Turbo model came equipped with the R200 with stronger Half shaft axels and thicker driveshaft.

The R200 and Half Axels pulled from a 1985 300ZX Turbo

I pulled this from the salvage yard, the axles according to Chilton Manual are the “Double Offset BirField” Type from the image. The text says the 1985 300ZX Turbo model came with the “Tripod” Type. There seems to be some misinformation there, Im a 240z guy, any info would help guys!

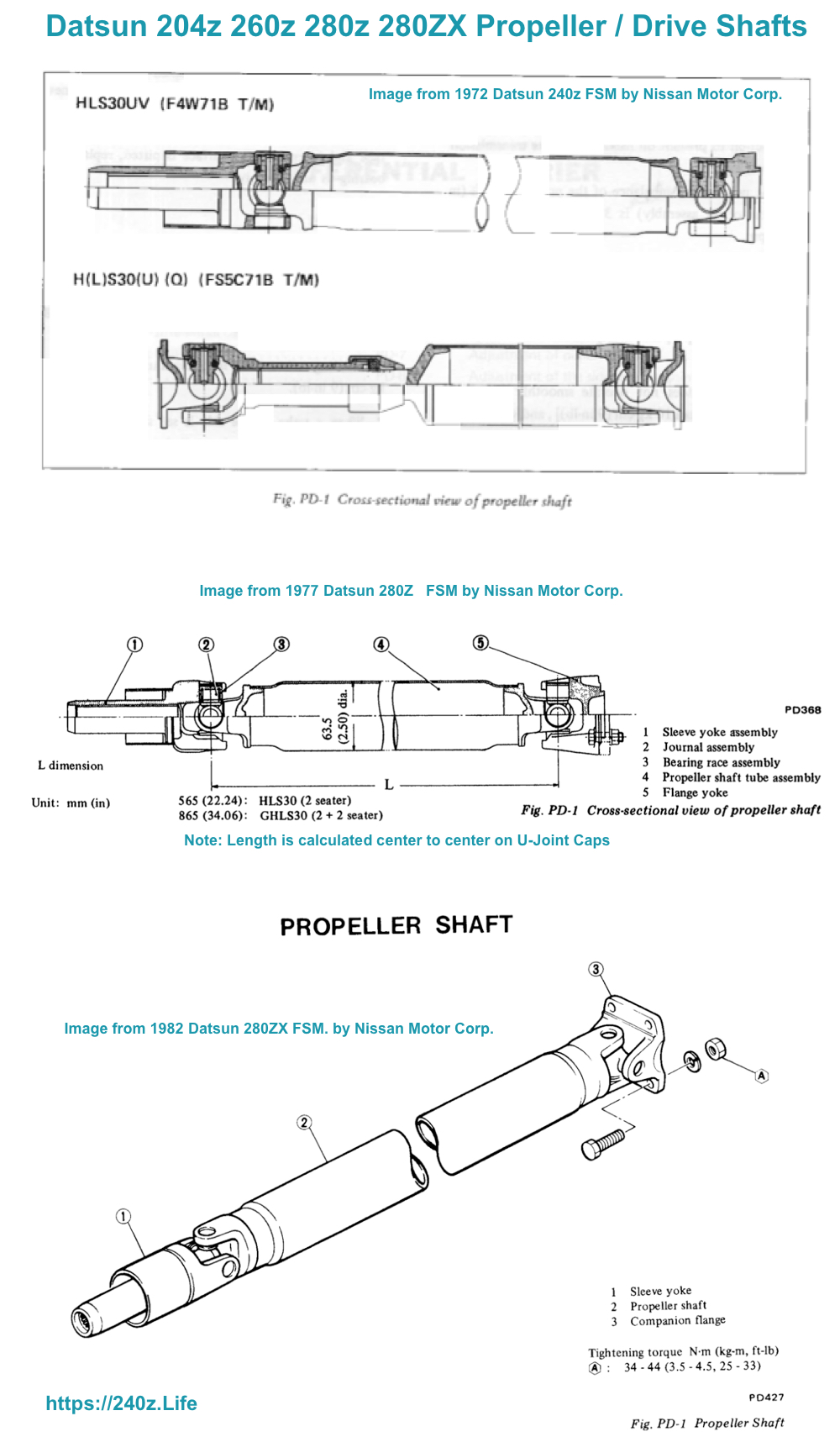

Datsun 240z 260z 280z 280ZX Propeller / Drive Shaft

There were at least 8 different drive shafts, varying in length and diameter for the various models based on Transmission, 2 Seater and 2+2 Seater, Non-Turbo and Turbo models. There is no info on the specs for the early 240z driveshafts. Please see spreadsheet for Length and Width Specs.